The fourslide does this action quickly and repeatedly, time and again, producing a large quantity of identical products in a short period of time. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

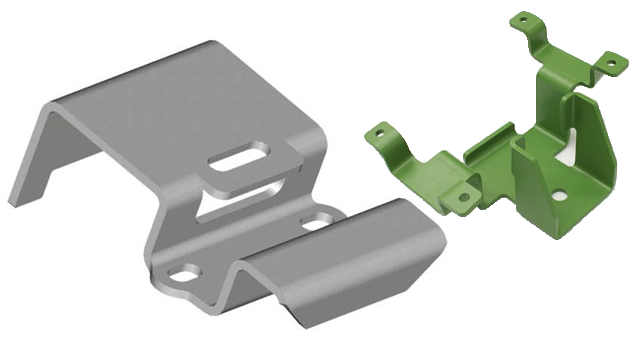

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

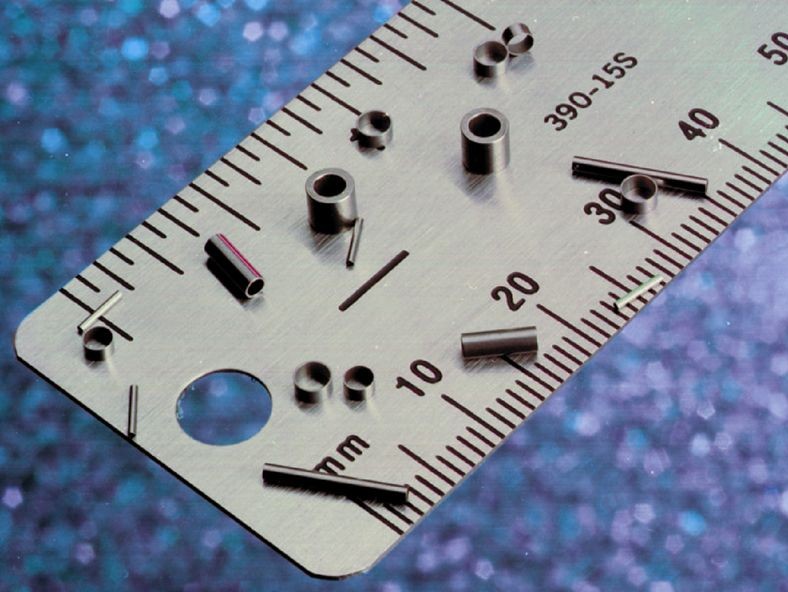

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

CSS is a leading international manufacturer of precision springs and metal shaped components. We have been a strategic supplier of progressive stampings, fineblanked stampings, machined stampings, springs and assemblies for 86 years. CSS serves OEMs in a wide variety of industries including medical, aerospace, defense/firearms, automotive, electronics and consumer products.

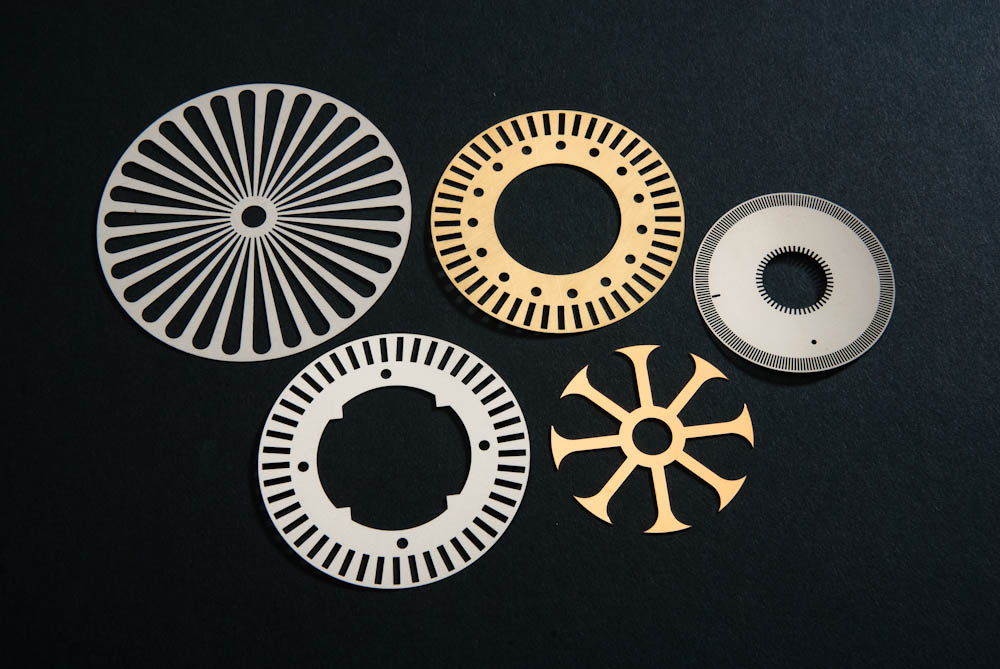

At Acorn Stamping, we specialize in precision metal stamping that meets the highest standards of accuracy, repeatability, and performance. With decades of experience and a deep understanding of material behavior, we deliver stamped components that serve a wide range of industries, including automotive, electronics, and industrial manufacturing.

More Fourslide Stamping Companies

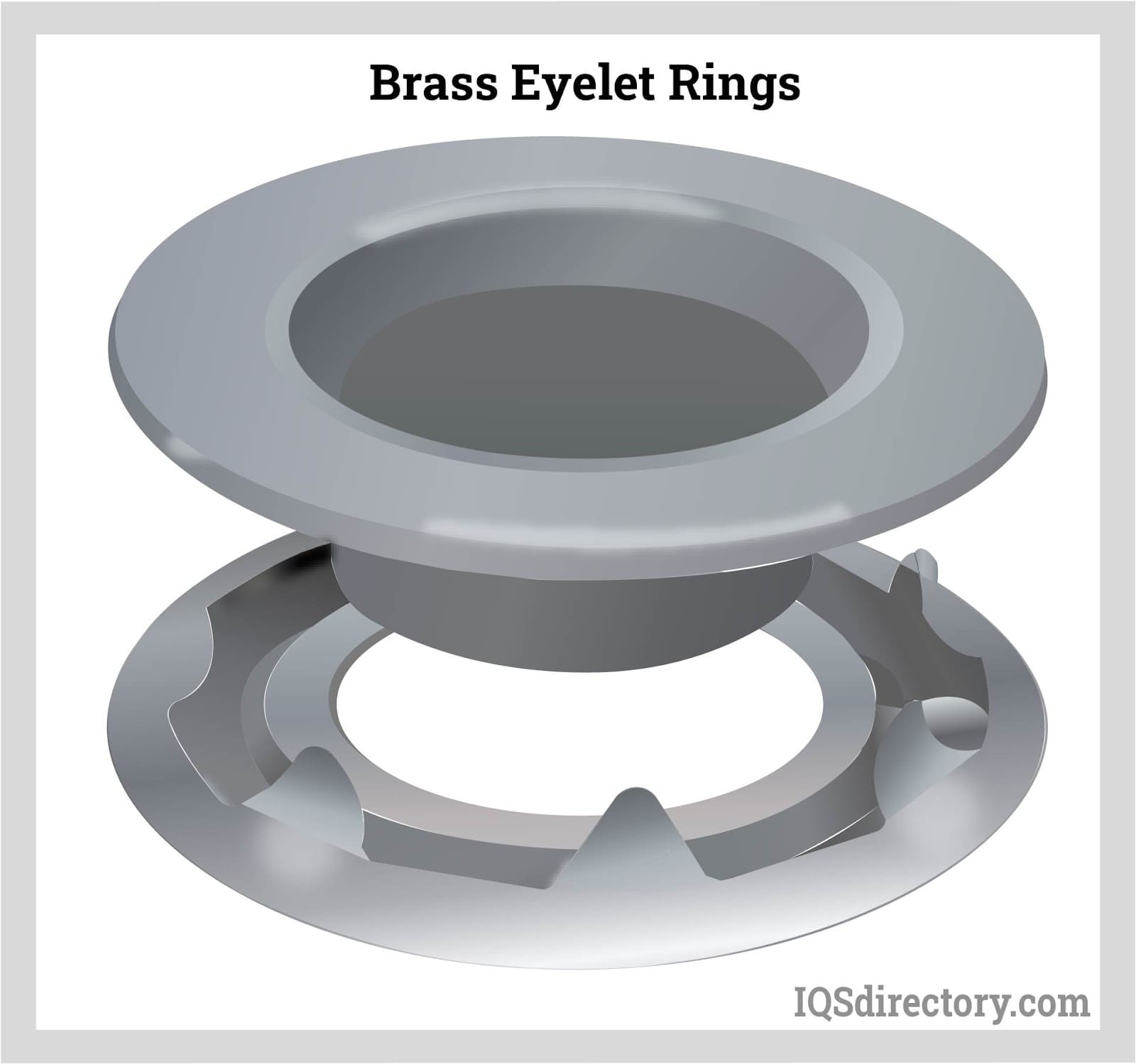

Fourslide machines are economically beneficial for manufacturing intricate parts like metal springs, wire forms, and stampings from metal strips or wires. Some common metallic materials that undergo fourslide stamping are aluminum, bronze, steel, cropper and many more.

Fourslide stamping is particularly advantageous for those applications that cannot be accomplished on a regular press without additional secondary processes can be easily made with fourslide machines. Fourslide machines have several beneficial features over other metal stamping processes including a high level of accuracy, repeated results, and a reduced cost in tooling fees.

Often used to form electronic stampings, additional applications of fourslide stampings include: in the automotive industry, for use as brake flanges, engine bases, flywheel shrouds and more; and in industrial manufacturing, for parts and components such as gear and sprocket blanks, backing rings, balance clamps and conveyor flights.

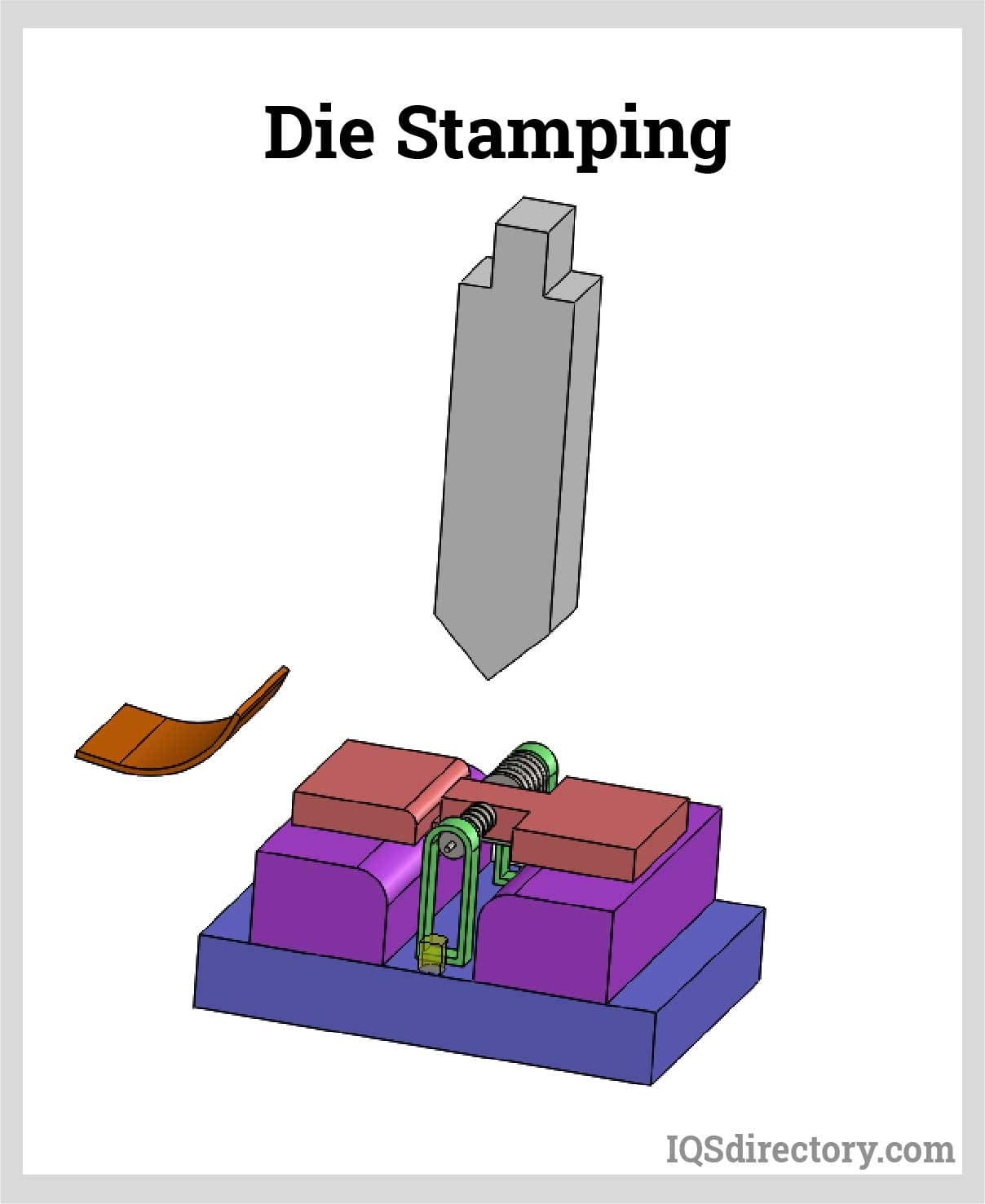

In a simplified explanation, a fourslide stamping press is the same as a horizontal stamping press with the addition of cams. In addition to cams, the basic design consists of shafts, an electric motor, a die, a press and the sliding tools. The four sliding tools achieve motion as a result of the shafts, which are connected by means of bevel gears to the electric motor.

In the fourslide stamping process, there are four sliding tools coming each from their own direction at the metal blank, typically a form of flat sheet metal, in order to bend the metal around a vertical mandrel and thus into a complex shape.

A timed mechanism known as a cam is used in order to regular the movement of the sliding tools. The cams are connected to the shafts for optimum control of the sliding tools' motion. As a result, fourslide stamping is able to incorporate the vertical movement provided by the punch with horizontal movement coming either simultaneously or successively from a number of directions from the sliding tools. Thus, the fourslide stamping more accurately is a reflection of the type of machine used to perform stamping, versus the actual process which could be one of a number of methods including transfer or progressive stamping.

Broaching

Broaching CNC Machining

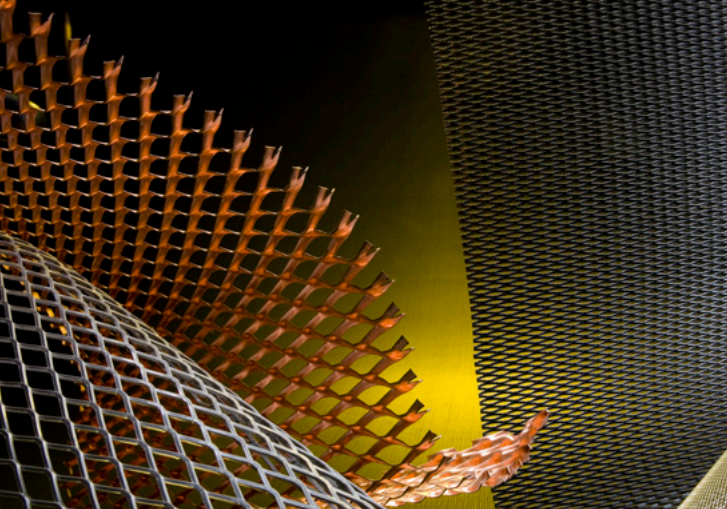

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

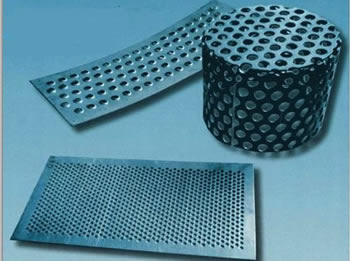

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

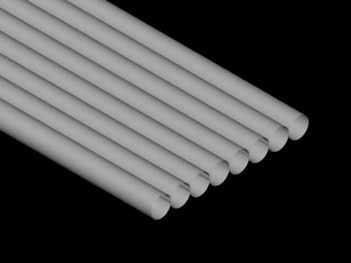

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services