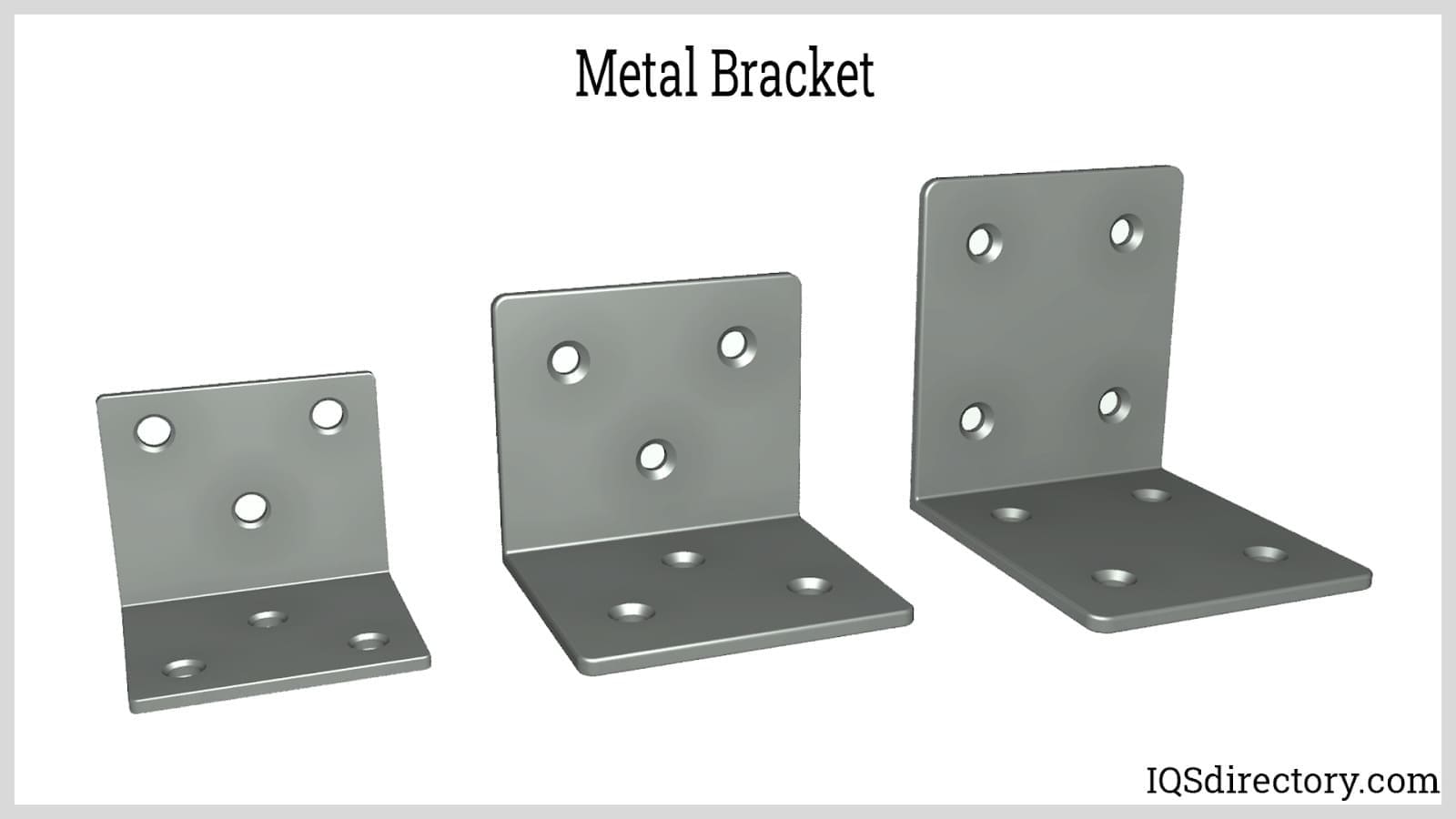

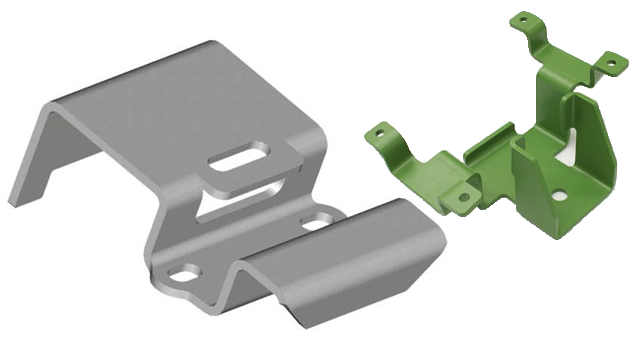

A metal bracket is an intermediate metal component used for fixing one part to another, e.g., a shelf to a wall. In addition to creating a connection between two parts, a metal bracket can be used to provide support. Metal brackets consist of two or more planes connected along one edge. The simplest and most common way to fabricate this object is to bend a flat object in two or more positions. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

CSS is a leading international manufacturer of precision springs and metal shaped components. We have been a strategic supplier of progressive stampings, fineblanked stampings, machined stampings, springs and assemblies for 86 years. CSS serves OEMs in a wide variety of industries including medical, aerospace, defense/firearms, automotive, electronics and consumer products.

At Acorn Stamping, we specialize in precision metal stamping that meets the highest standards of accuracy, repeatability, and performance. With decades of experience and a deep understanding of material behavior, we deliver stamped components that serve a wide range of industries, including automotive, electronics, and industrial manufacturing.

More Metal Bracket Companies

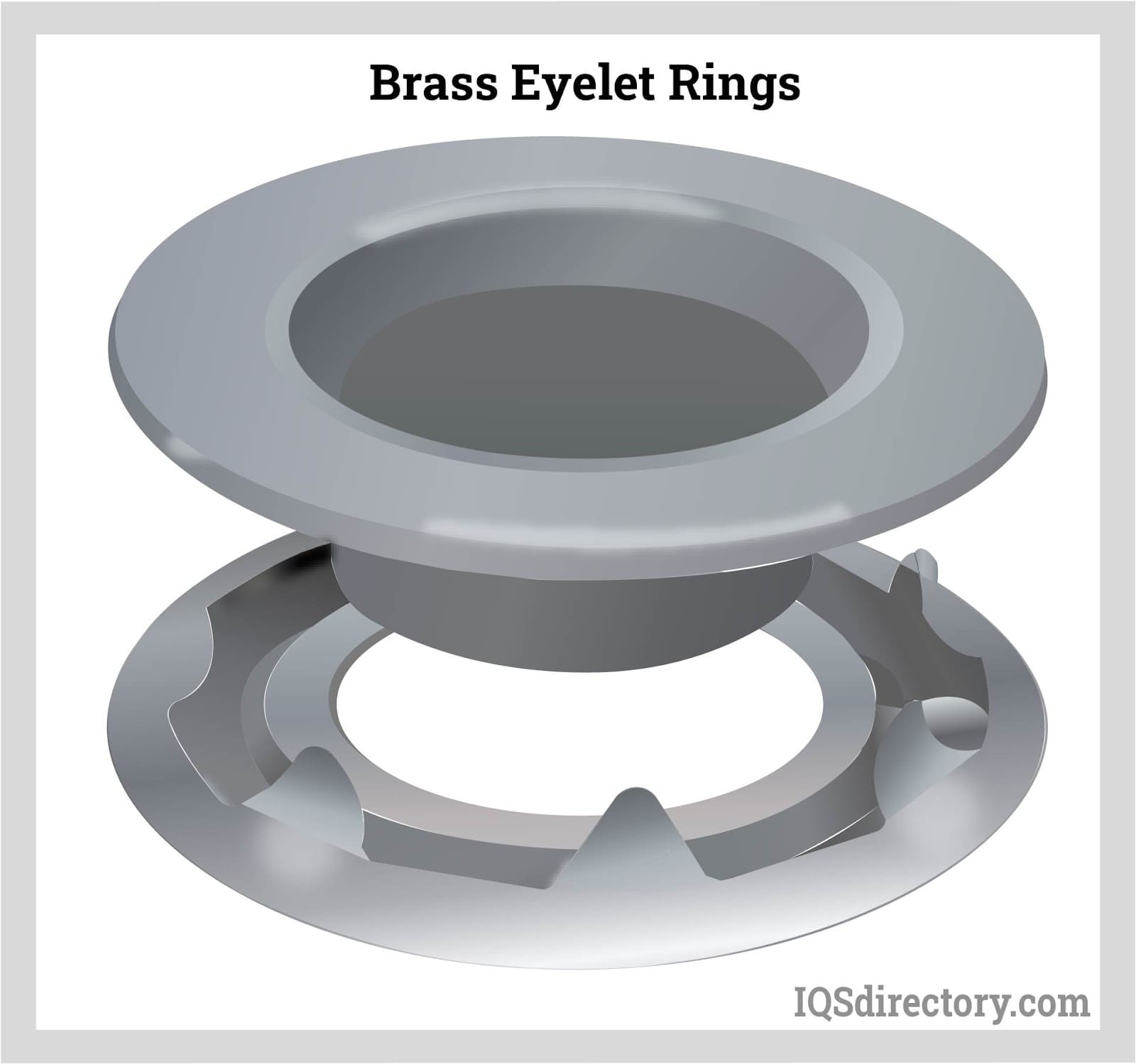

The easiest machining method would be to add a 90° bend to a flat rectangle with a straight profile, turning it into a metal bracket with an L-shaped profile. Metal brackets can support objects like countertops, shelving, mounted televisions, and furniture sections. Metal brackets can be stamped from various materials such as brass, copper, aluminum, and stainless steel. The metal brackets can also be coated with a variety of materials to enhance their appearance. The application of the metal bracket will affect the type of material it is stamped from, the shape, and the appearance.

How Brackets Are Made

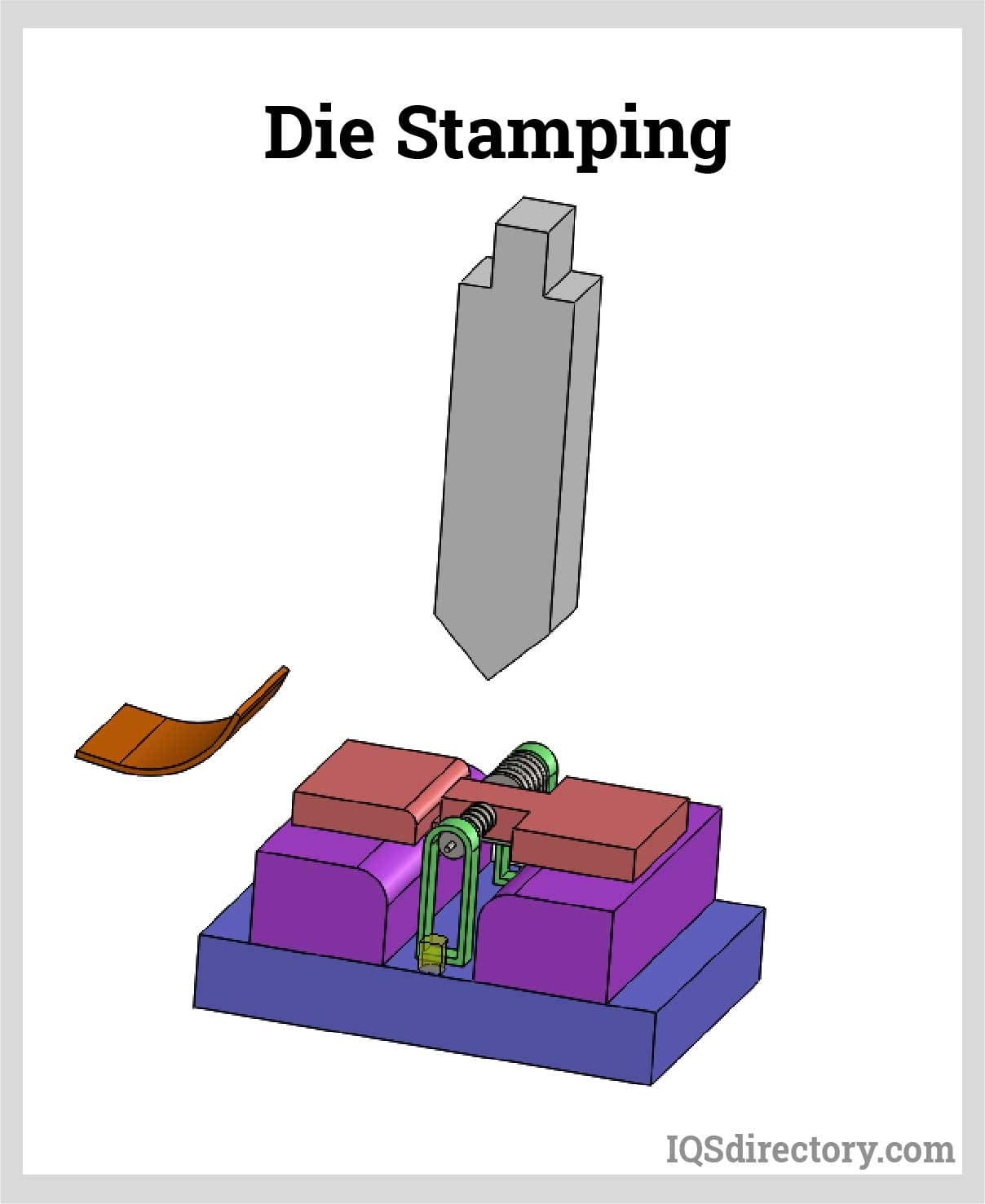

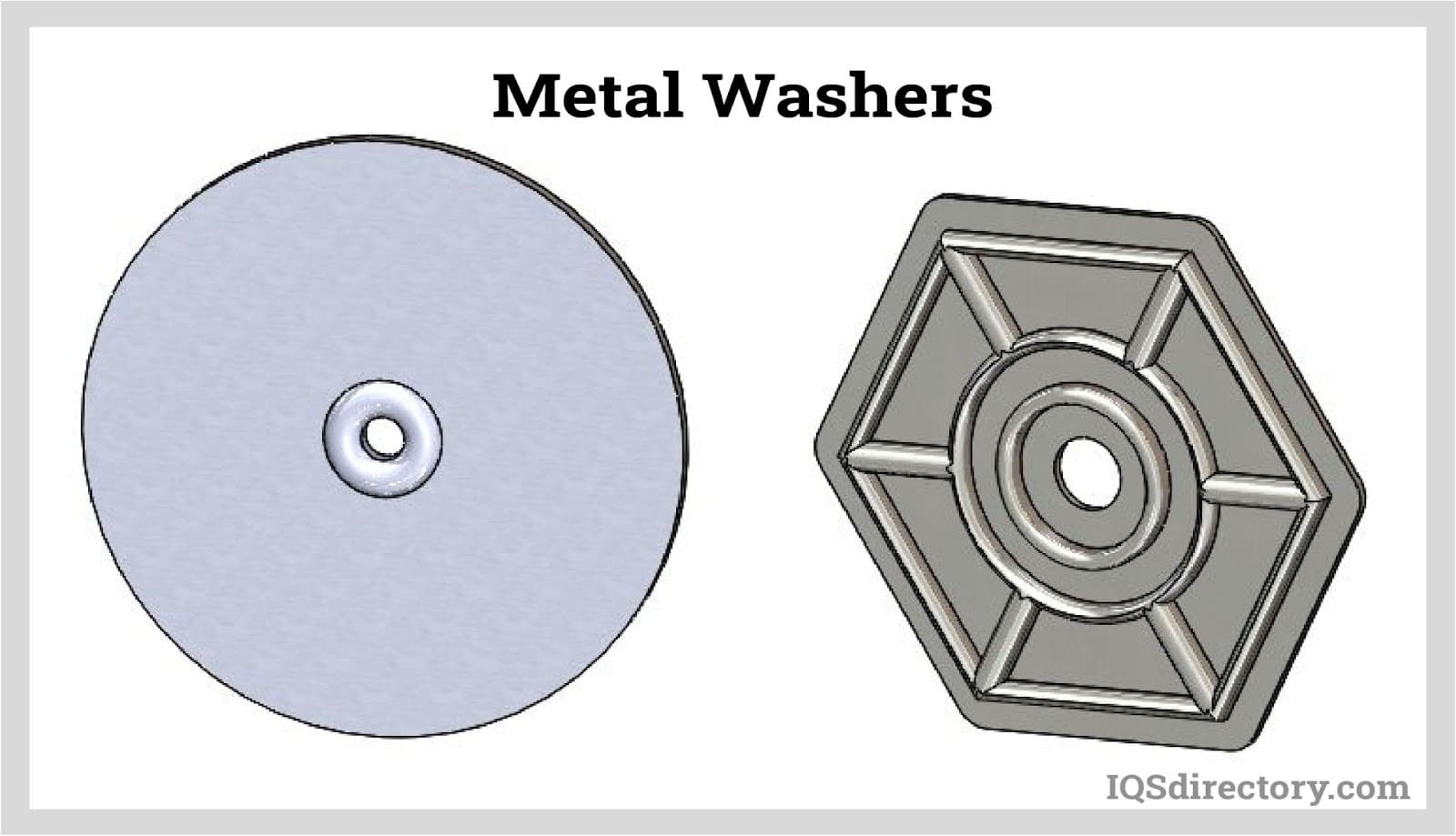

Metal brackets can be made in various ways, which include casting or CNC machining. However, the ideal way to make brackets is by sheet metal fabrication. One of the processes commonly used for sheet metal fabrication is bending. In this process, a machine called a bend is used to bend sheet metal to an angle up to 120°. This process is important since all brackets virtually incorporate at least one bend. Before any sheet bending process occurs, the sheet metal must be cut to size using a machine such as a plasma cutter or a laser cutter. A punching machine may be used to make holes in the bracket for fitting screws. Welding is also required in the addition of gussets or other related features.

Types of Metal Brackets

Bracket varieties vary based on the application and the objects they are designed to support. Some of the configurations for metal brackets include L-brackets, J-brackets, Box brackets, U-brackets, Z-brackets, and gusset brackets. J-brackets are used in construction and often in automotive applications. They can also be found in structural applications in conjunction with L-brackets. Box brackets are also named square brackets, and these are one of the strongest types of metal brackets.

L-Bracket

An L-bracket is one of the commonly used bracket types. The L-bracket contains an L-shaped profile after being bent along a single axis, creating a 90° angle at most. The L-bracket is used in many applications where a horizontal object needs mounting to a vertical object.

This scenario may be seen in mounting a shelf to a wall. The L-bracket is widely used in decorative and structural applications.

U-Bracket

Unlike the L-bracket, the U-bracket is bent along two axes, forming a U-shaped profile. The U-brackets can be used to grip an object between its flanges or mount two horizontal parallel objects above the other.

Z-Bracket

A Z-bracket is a type of metal bracket that incorporates two bends. However, unlike a U-bracket in which two bends are formed on the same face of the metal sheet, the Z-bracket bends one flange inwards and the other outwards to make a Z-shaped profile. As a result, the Z-brackets can be used to mount surfaces that are parallel and offset from one another.

Gusset Bracket

The gusset bracket is a metal bracket supported with extra material to improve its load-bearing capacity and strength. The gusset bracket is like an L-bracket but with an extra triangular section of material between the horizontal and vertical sections.

The gussets can be welded onto the bracket or included within a single piece. In the latter, the vertical and horizontal faces of the bracket are bent from the edges of the triangle.

Applications and Uses of Metals Brackets

Metal brackets are often used for decorative purposes. In decorative applications, the metal brackets can be powder coated in colors such as white, gray, etc., to be more aesthetically pleasing. Metal brackets can be used in the telecommunications, electronics, construction, automotive, defense, commercial, dental, architecture, and aerospace industries.

Choosing the Right Metal Brackets Manufacturer

To make sure you have the most positive outcome when purchasing Metal Brackets from a Metal Brackets Manufacturer, it is important to compare at least 5 or 6 Manufacturers using our list of Metal Brackets suppliers. Each Metal Brackets Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Metal Brackets business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Metal Brackets companies with the same form.

Broaching

Broaching CNC Machining

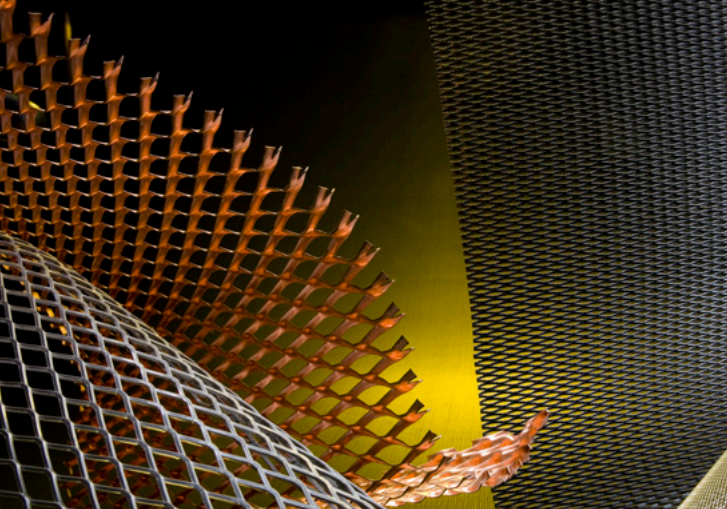

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

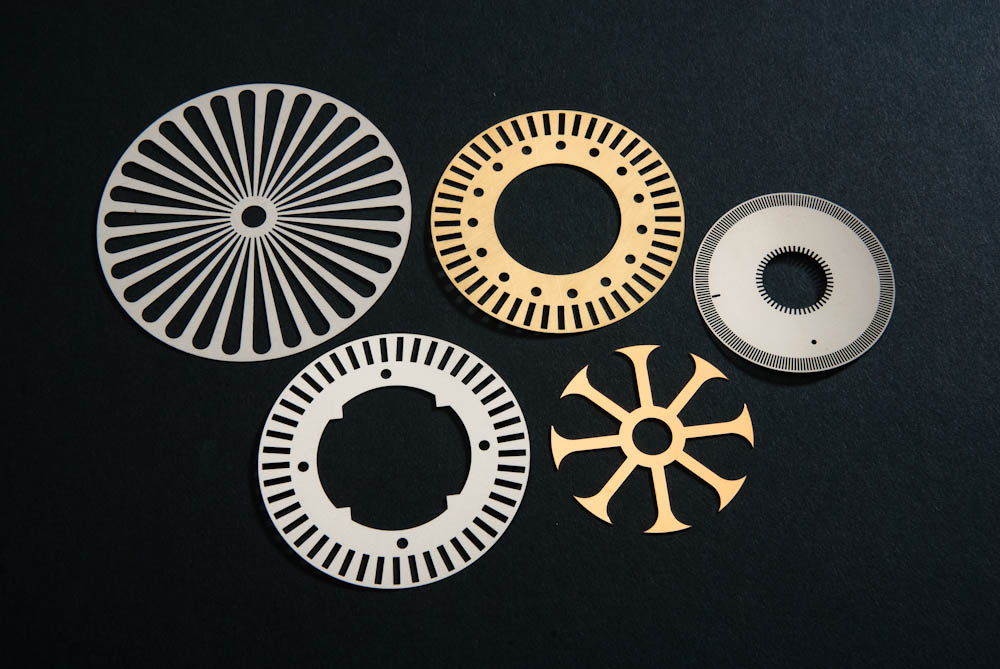

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

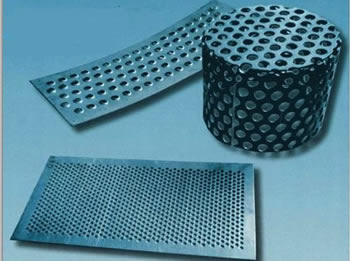

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

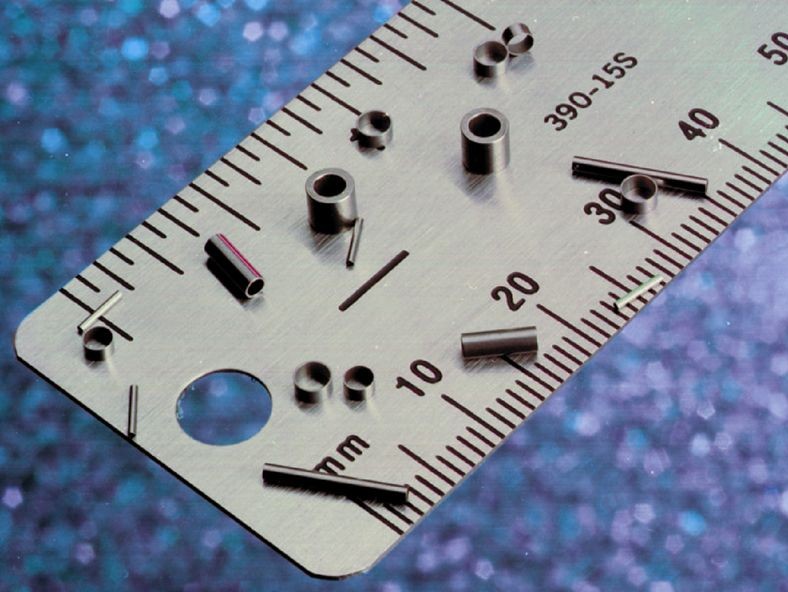

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services