Stainless steel stampings are metal components created through a variety of manufacturing processes that involve forming, punching, and bending stainless steel sheets into desired shapes. These stampings are commonly used in a wide range of industries, such as automotive, aerospace, construction, medical, and electrical. They are known for their durability, corrosion resistance, and aesthetic appeal, among other benefits. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

CSS is a leading international manufacturer of precision springs and metal shaped components. We have been a strategic supplier of progressive stampings, fineblanked stampings, machined stampings, springs and assemblies for 86 years. CSS serves OEMs in a wide variety of industries including medical, aerospace, defense/firearms, automotive, electronics and consumer products.

At Acorn Stamping, we specialize in precision metal stamping that meets the highest standards of accuracy, repeatability, and performance. With decades of experience and a deep understanding of material behavior, we deliver stamped components that serve a wide range of industries, including automotive, electronics, and industrial manufacturing.

More Stainless Steel Stamping Companies

The Creation of Stainless Steel Stampings

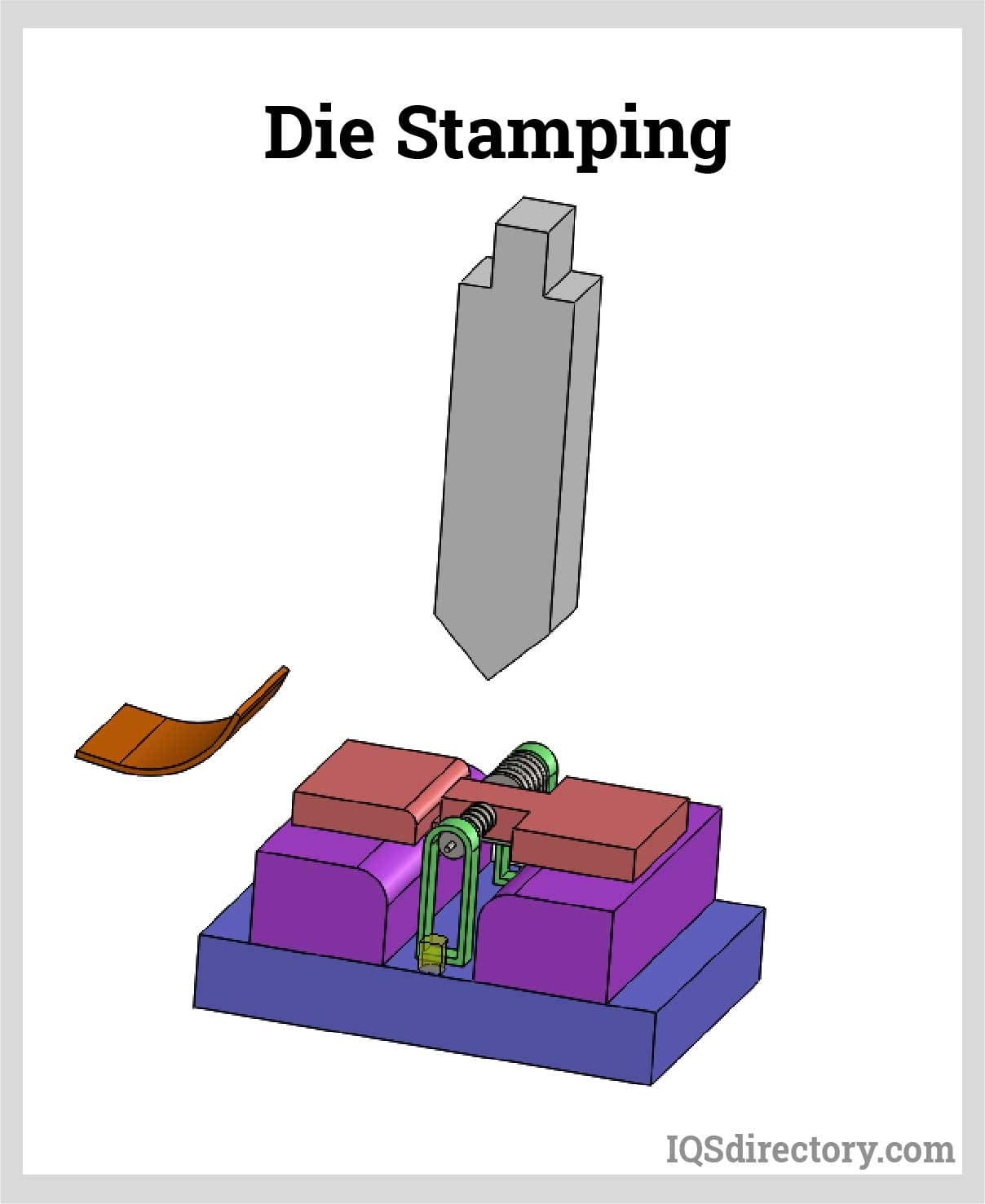

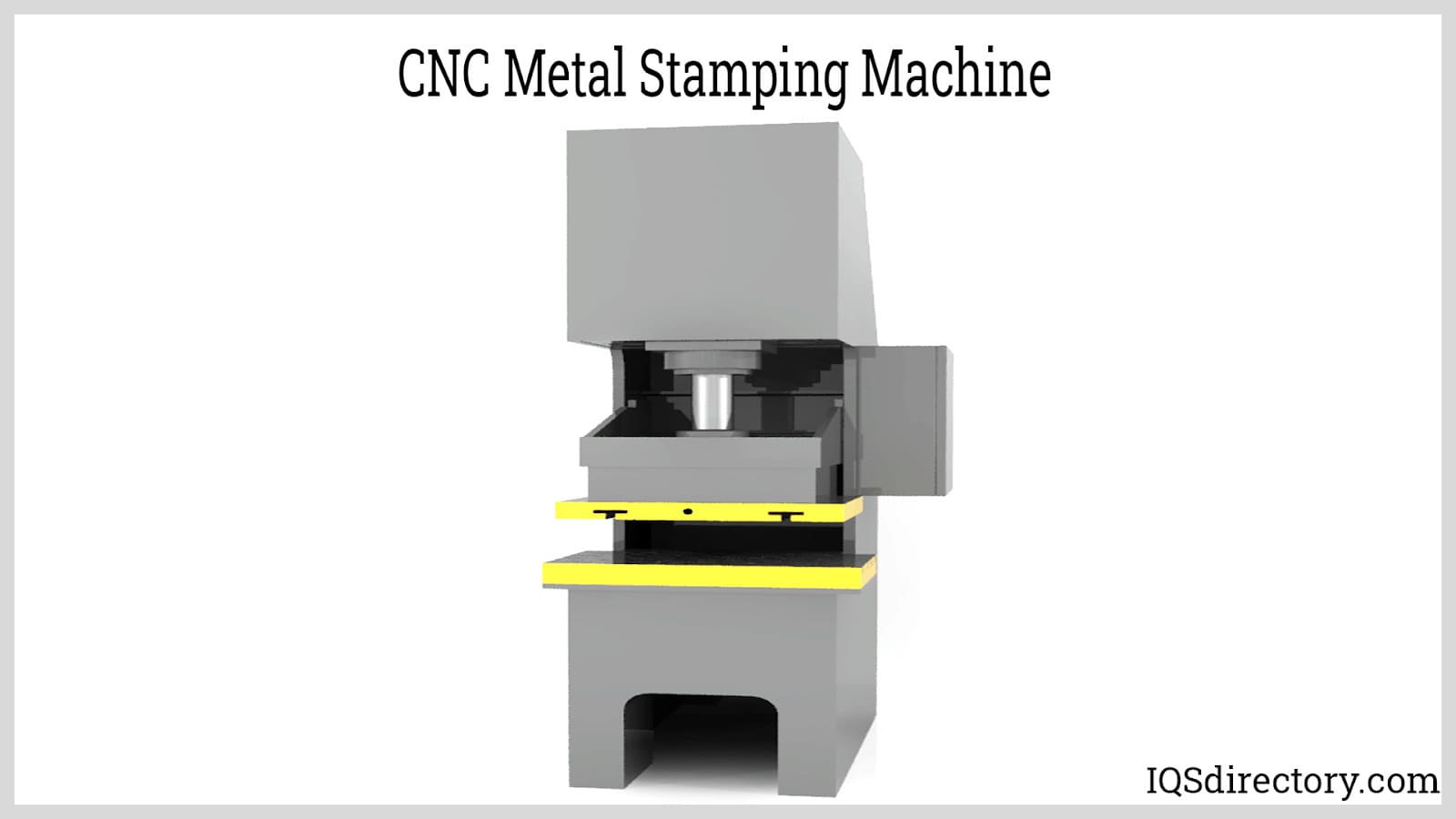

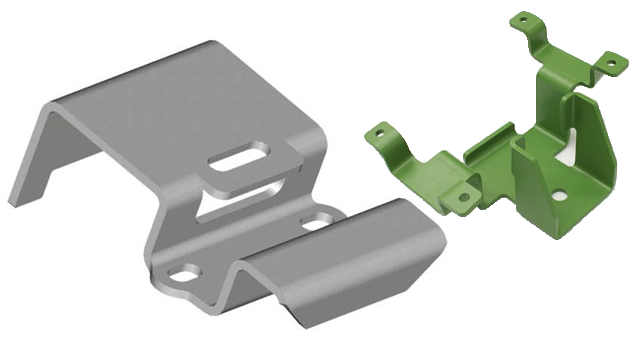

There are different processes used in creating stainless steel stampings, each with its own set of advantages and disadvantages. The most common processes include progressive die stamping, four-slide stamping, and deep draw stamping. Each process is explained below.

Progressive Die Stamping

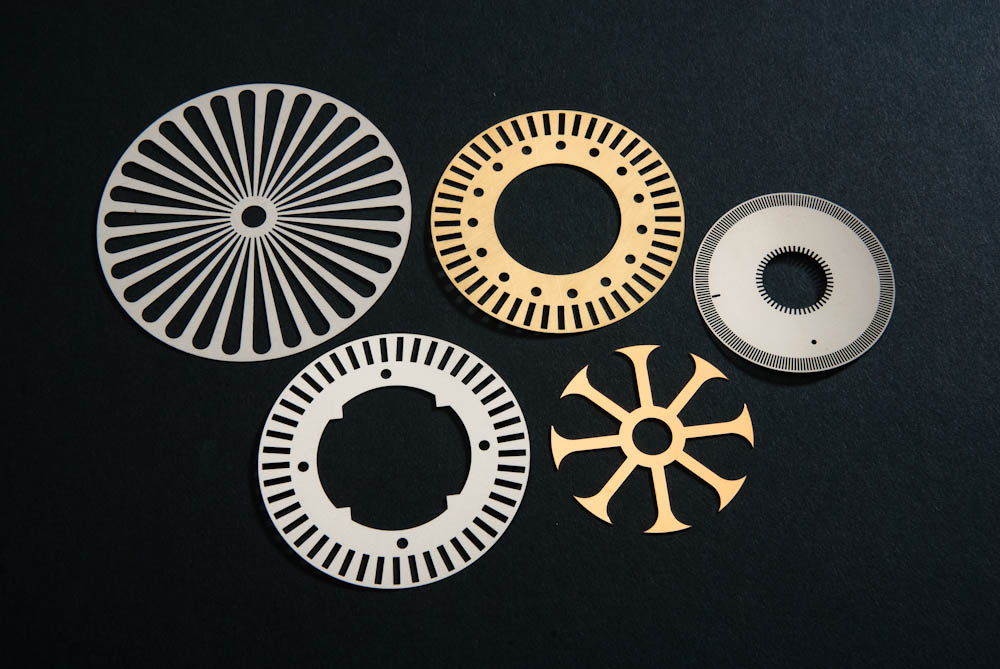

Progressive die stamping involves using a series of dies, each of which performs a specific operation on the metal sheet, resulting in a complex final product. This process is suitable for high-volume production and offers excellent precision and repeatability. It is commonly used in the automotive industry, where complex parts with tight tolerances are required.

Four-Slide Stamping

Four-slide stamping is a versatile process that can produce intricate and complex shapes. It involves a machine with four different slides that work together to shape the metal sheet. This process is ideal for low-volume production and can be used to manufacture parts for the medical, electrical, and consumer goods industries.

Deep Draw Stamping

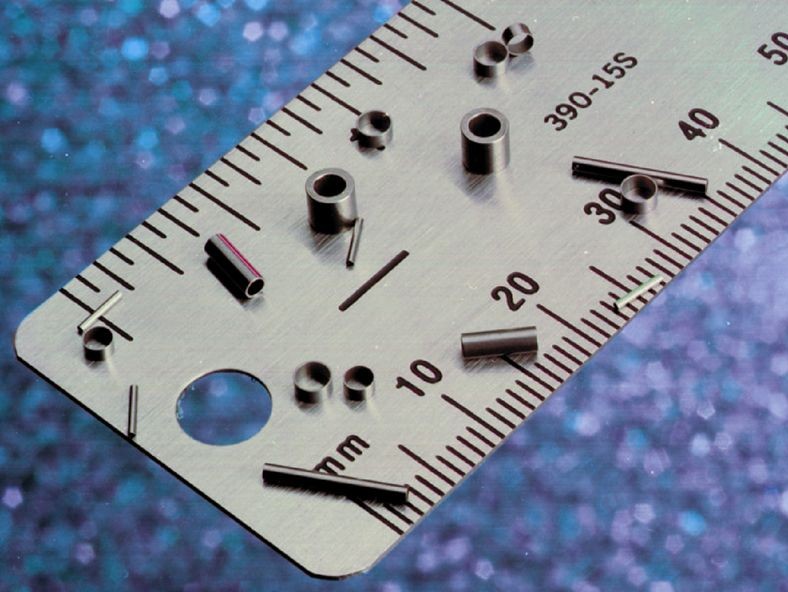

Deep draw stamping is used to create parts with deep cavities, such as cups, cans, and cylinders. The process involves drawing the sheet metal into a die cavity using a punch, resulting in a seamless and uniform product. Deep draw stamping is commonly used in the food and beverage industry, where sanitary and corrosion-resistant components are required.

Laws and Regulations Pertaining to Stainless Steel Stampings

Stainless steel stampings are subject to various laws and regulations in the United States, which aim to ensure that they meet safety, health, and environmental standards. Here are some regulations and organizations that could impact stainless steel stampings in the United States:

Occupational Safety and Health Administration (OSHA)

OSHA has several standards that may apply to the manufacturing of stainless steel stampings, including:

The General Duty Clause

The general duty clause requires employers to provide a workplace free from recognized hazards that can cause serious harm or death.

The Standard for Machine Guarding

The standard for machine guarding, which requires the use of safeguards on machines to protect workers from hazards such as pinch points, rotating parts, and flying debris.

The Standard for Personal Protective Equipment (PPE)

The standard for personal protective equipment requires employers to provide and ensure the use of appropriate PPE to protect workers from hazards such as cuts, punctures, and eye injuries.

The Environmental Protection Agency (EPA)

The EPA regulates the disposal of hazardous waste generated during the production of stainless steel stampings. The Resource Conservation and Recovery Act (RCRA) requires that hazardous waste be managed and disposed of in a manner that protects human health and the environment. The EPA also regulates air emissions from manufacturing processes through the Clean Air Act (CAA).

Consumer Product Safety Commission (CPSC)

The CPSC enforces safety standards for consumer products, including stainless steel stampings used in consumer goods. The Federal Hazardous Substances Act (FHSA) requires warning labels on products that contain hazardous substances. Additionally, the Consumer Product Safety Improvement Act (CPSIA) sets limits on lead and other toxic substances in consumer products.

The Toxic Substances Control Act (TSCA)

The Toxic Substances Control Act regulates the use of chemicals in commerce, including those used in the production of stainless steel stampings.

The Clean Water Act (CWA)

The Clean Water Act regulates the discharge of pollutants into surface waters. State laws may also regulate the disposal of hazardous waste and the use of chemicals in manufacturing. It's important for manufacturers of stainless steel stampings to be aware of these regulations and laws to ensure compliance and avoid penalties.

Considerations Regarding Stainless Steel Stampings

Despite their many benefits, stainless steel stampings are not without their considerations. The manufacturing process can be energy-intensive, resulting in high carbon emissions and environmental impacts. The disposal of waste generated during the process can also be challenging and expensive. Moreover, workers who handle stainless steel stampings are at risk of injury from sharp edges and heavy machinery.

Benefits of Stainless Steel Stampings

Despite these considerations, stainless steel stampings offer numerous benefits that make them a popular choice in various industries. They are durable and resistant to corrosion, making them ideal for use in harsh environments. They are also versatile and can be customized to suit specific applications. Additionally, they are cost-effective and efficient, as they can be mass-produced and assembled quickly. Finally, they have an aesthetic appeal that makes them suitable for use in high-end consumer goods.

Applications of Stainless Steel Stampings

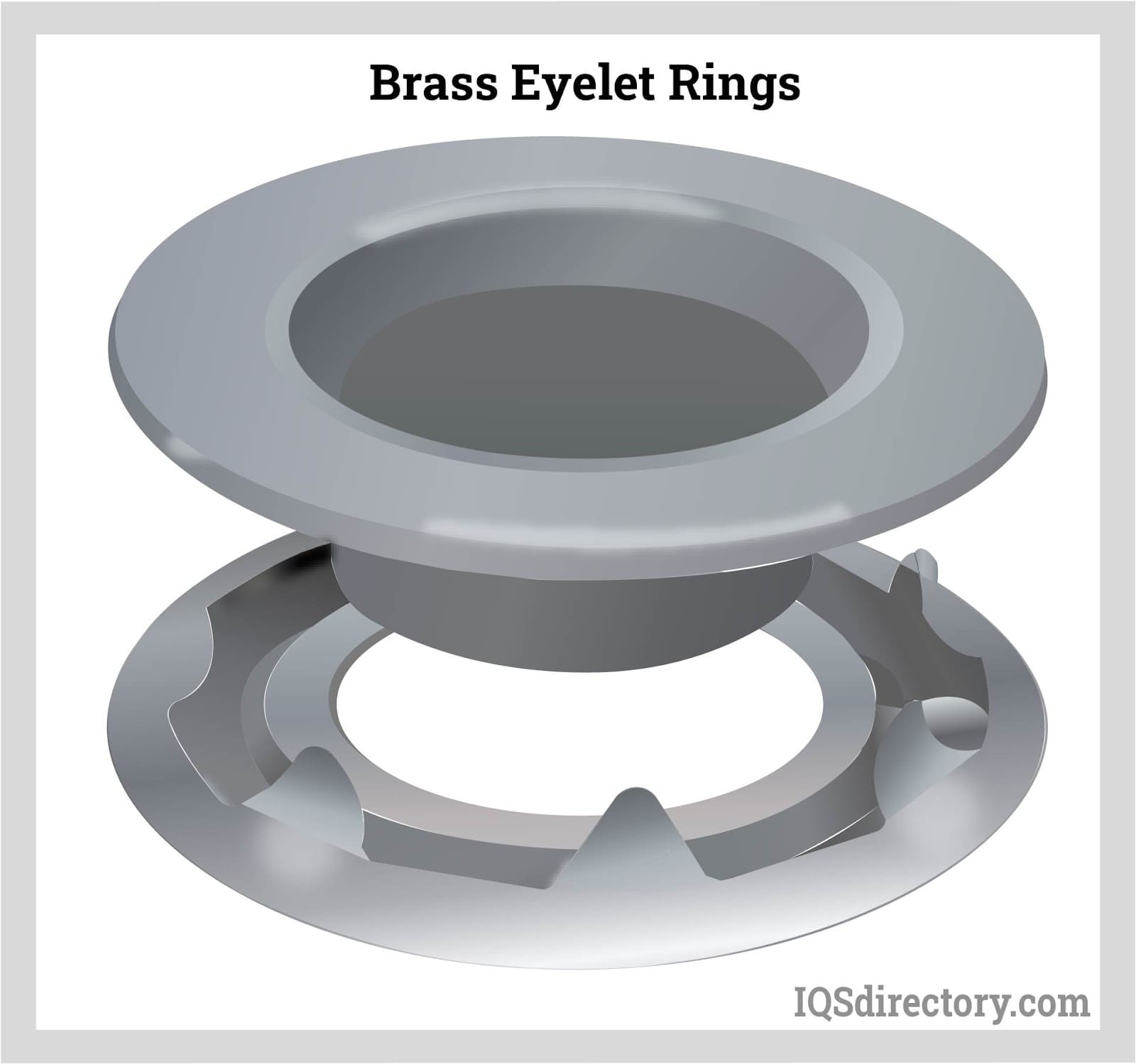

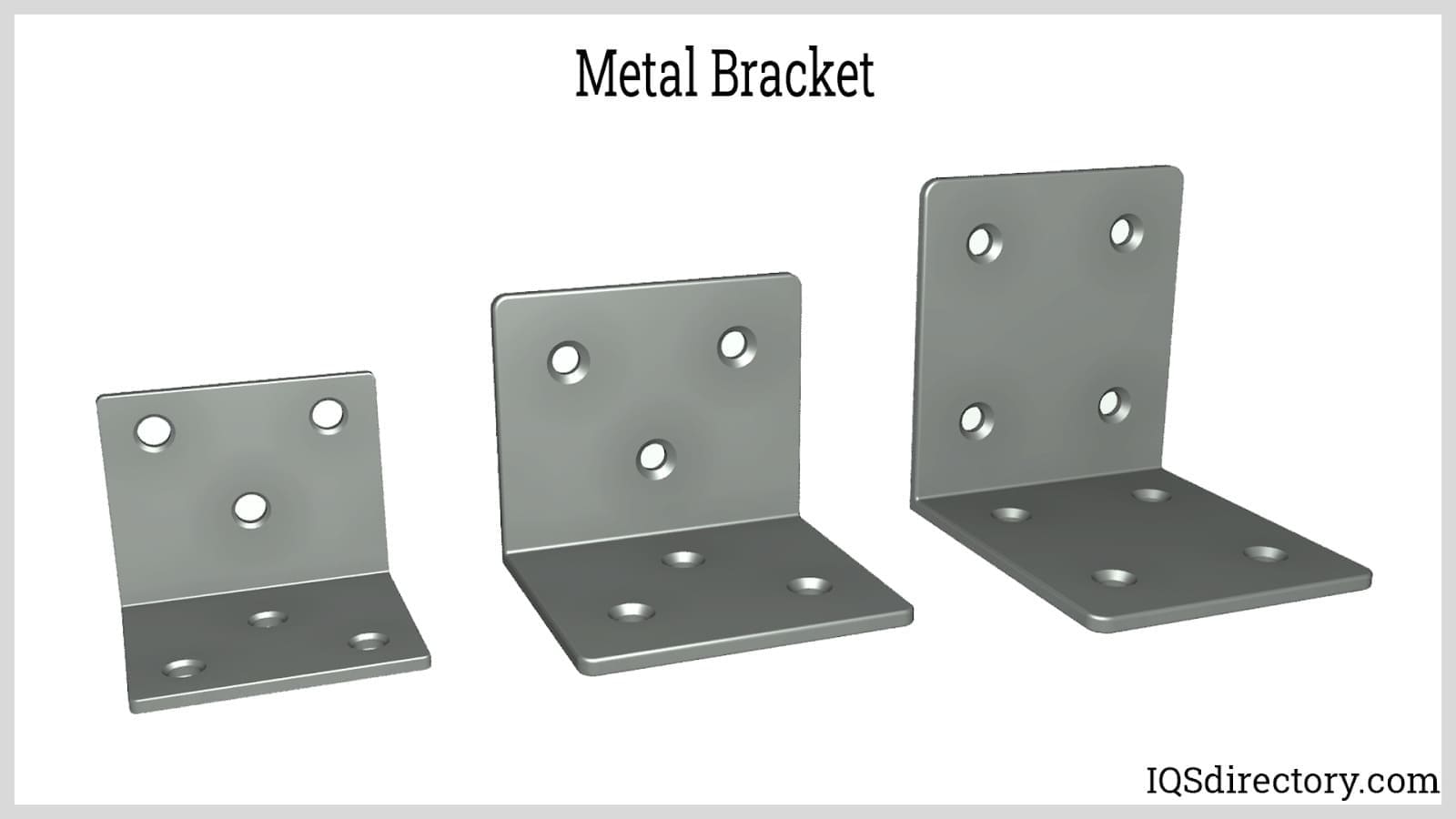

Due to their many benefits, stainless steel stampings are used in a wide range of applications and various industries.Stainless steel stampings can be used to manufacture food processing equipment components such as valves and fittings due to their corrosion resistance and ability to withstand high temperatures and pressures. In the automotive industry, meanwhile, they are used in engine components, brake systems, and suspension parts. In the aerospace industry, they are used in aircraft components, such as wing flaps and landing gear. In the construction industry, they are used in architectural elements, such as handrails and balustrades. In the medical industry, they are used in surgical instruments and medical implants. In the electrical industry, they are used in components such as battery contacts and connectors. They are also used in consumer goods, such as kitchenware, and furniture hardware. In short, the versatility of stainless steel stampings makes them useful in many different applications.

Choosing the Correct Stainless Steel Stampings Manufacturer

To ensure you have the most productive outcome when purchasing stainless steel stampings from a stainless steel stampings manufacturer, it is important to compare several companies using our directory of stainless steel stampings manufacturers. Each stainless steel stampings manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information, or to request a quote. Review each stainless steel stampings business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple stainless steel stampings companies with the same form.

Broaching

Broaching CNC Machining

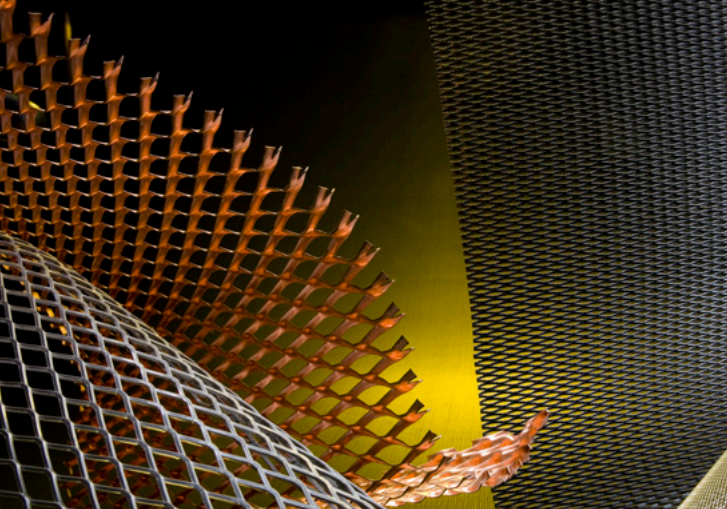

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

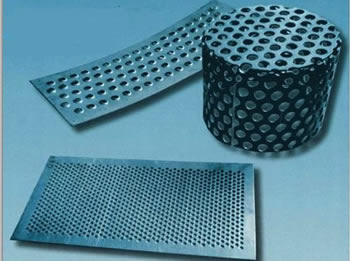

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services