More Metal Stamping Companies

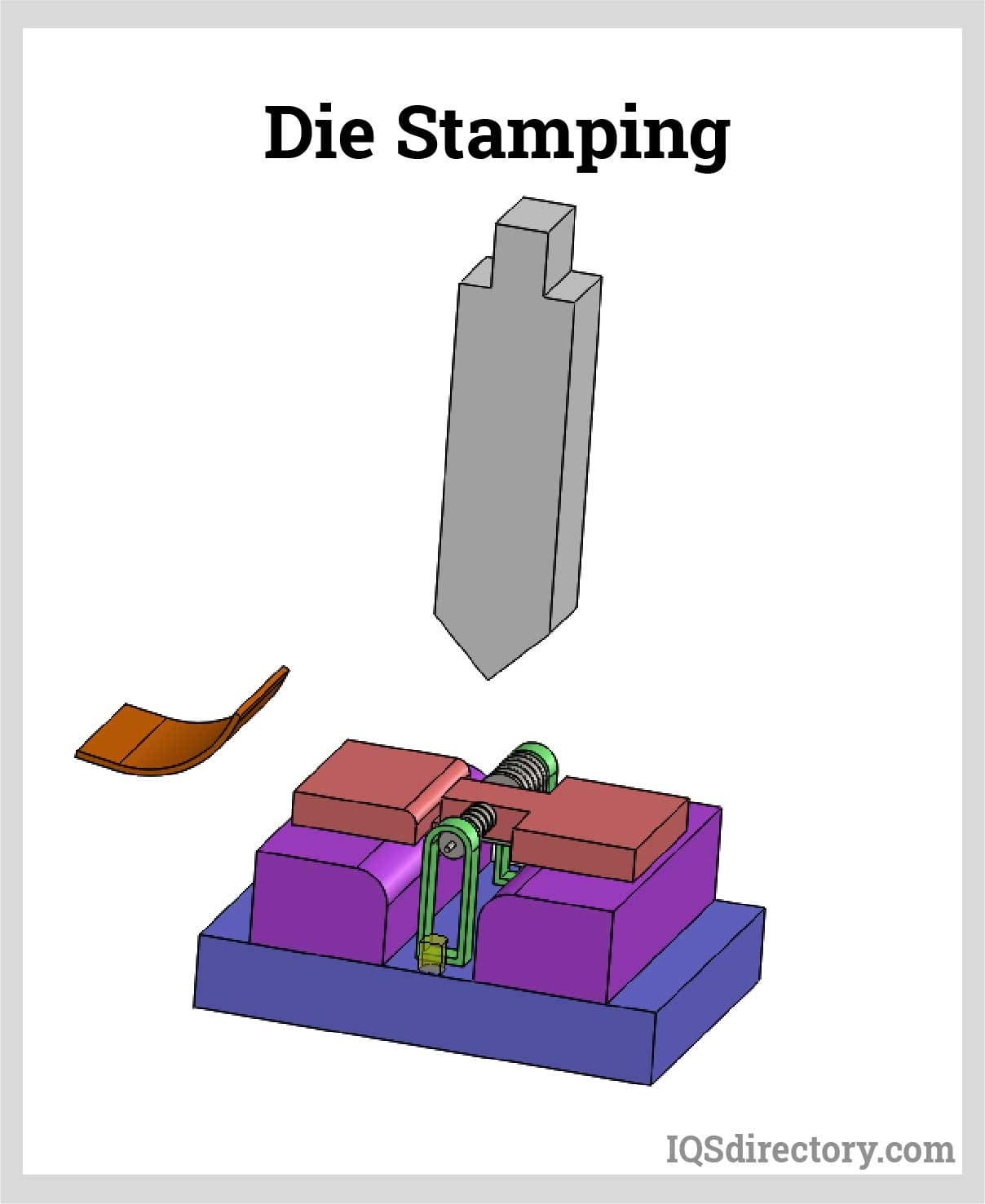

Apart from stamping, the term “metal stamping” encompasses a range of metalworking techniques performed using a press machine. These techniques include bending, blanking, coining, embossing, flanging, forging, and punching.

Applications

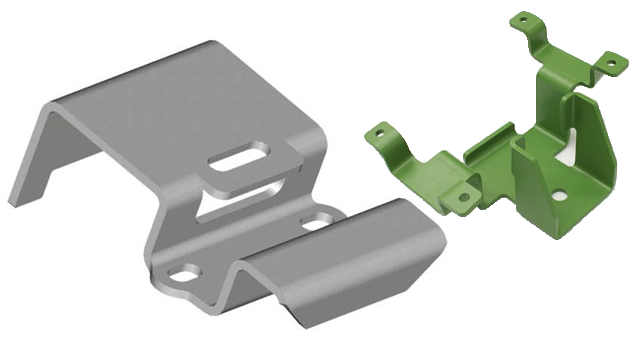

Metal stampings are indispensable across diverse industries, prized for their adaptability and economical benefits. Notably, in automotive manufacturing, they play a crucial role in crafting body panels, brackets, hinges, and engine parts. Their precise fabrication supports high-volume production, meeting the demanding specifications required in the automotive sector. Beyond automotive, metal stampings are vital in electronics, where they shape connectors, terminals, and device contacts, leveraging their robustness for reliable electrical performance. In aerospace, these stampings form key components like brackets, frames, and fasteners, valued for their lightweight yet robust properties that enhance efficiency and safety in aircraft. In consumer goods, from appliances to furniture and hardware, metal stampings excel in providing durability, functionality, and aesthetic appeal, serving critical roles in hinges, latches, and decorative elements. Overall, metal stampings are indispensable across industries, enabling the creation of top-tier components with precision, efficiency, and cost-effectiveness.

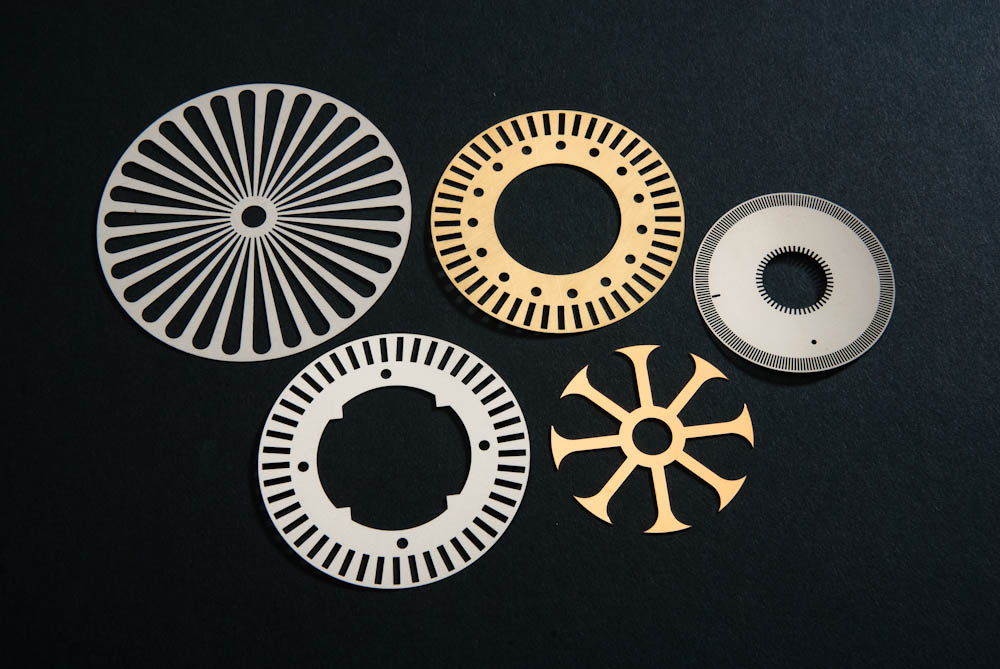

Products Produced

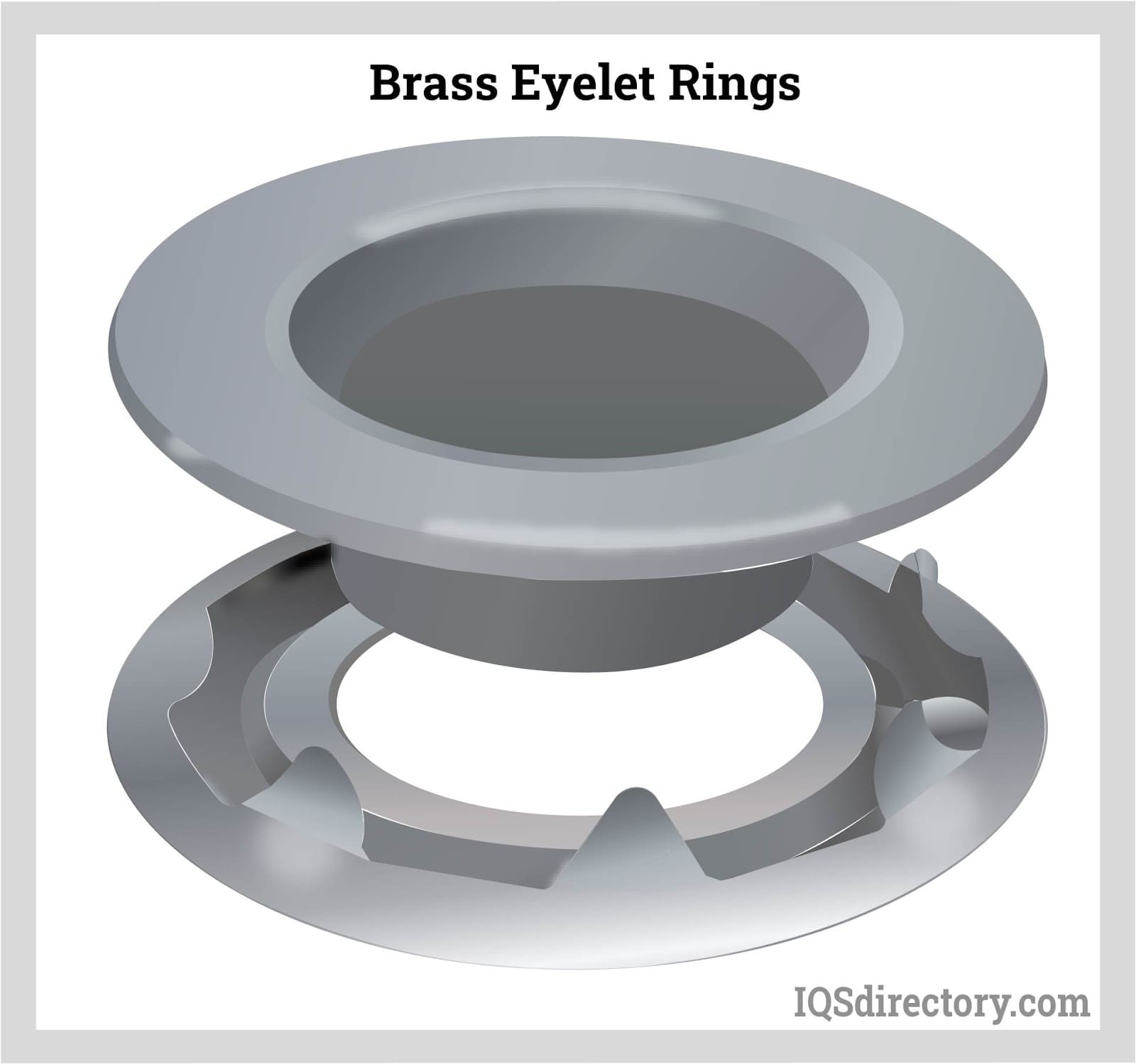

Metal stamping enables manufacturers to create a vast array of products. From essential items like deep drawn stampings (such as pots and pans), metal brackets, spring clips, and exterior building panels (including roofs, doors, bonnets, side panels, deck lids, and fenders), to interior building panels, metal brackets, eyelets, precision tools like lasers and gauges, radio system components, medical equipment, helicopter and vehicle engine parts, weaponry components, navigation systems, landing gears, and crucially precise panels. Moreover, metal stamping serves diverse applications such as crafting jewelry, household essentials, and plumbing fixtures.

History

The first recorded instances of metal stampings can be traced back to coins crafted by the Lydians in the 7th century BC. Residing in what is now modern-day Turkey, the Lydians devised a method to create coins by sandwiching pieces of gold or gold alloy between a die bearing one image and a stamp imprinted with another. With the metal precisely positioned, they would then strike the assembled die and stamp with a forceful hammer blow.

This metal stamping technique persisted until 1550 when German silversmith Marx Schwab revolutionized the process by inventing a sizable metal press that worked in tandem with the die. Capable of accommodating up to 12 workers simultaneously, Schwab’s creation, known as the screw press, marked a significant leap in metalworking technology.

Metal stamping truly found its footing in the era of the Industrial Revolution. It began with manufacturers harnessing this technique to shape bicycle components. Discovering its cost-effectiveness and efficiency, they rapidly expanded its use to a wide array of products. By the dawn of the 20th century, Henry Ford adopted metal stamping for crafting parts for his iconic automobile, the Model T.

Since its inception, the metal stamping process has largely remained the same, with the primary changes being the introduction of automation, the diversification of power sources such as electricity, pneumatics, and hydraulics, and the expansion in the variety of materials suitable for stamping.

Metal stamping has woven itself into the fabric of our society, most notably within our automobiles. Back in 2014, the automotive stamping sector was appraised at a hefty $31 billion. On another front, the electronic stamping industry is on a swift ascent, projected to climb at a compound annual growth rate (CAGR) of 5.4% by 2022. Clearly, the currents are favorable for investments in metal stamping.

Materials Process

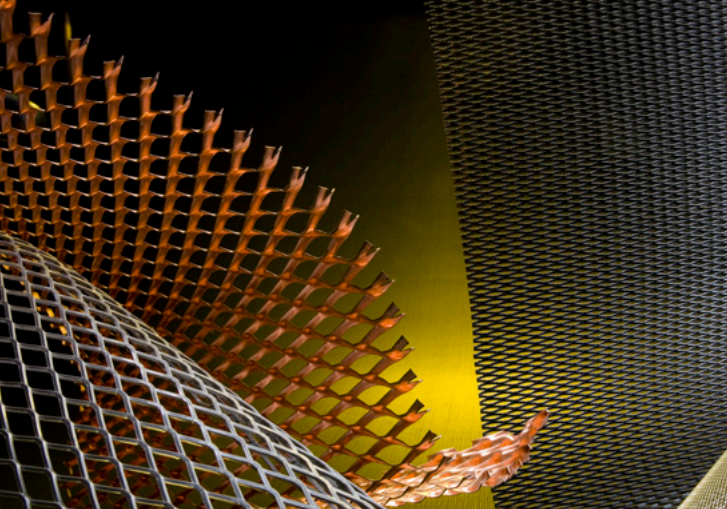

Metal stamping is versatile, accommodating a wide range of materials including zinc, nickel, steel, brass, aluminum, copper, titanium, and numerous alloys.

Zinc, a naturally occurring element, often serves as the foundation for alloys in the realm of metalworking. On its own, it presents as brittle and challenging to shape; however, when incorporated into alloys, it becomes a stalwart guardian against corrosion and galvanization. Notably, it plays a crucial role in the crafting of brass sheet metal.

Nickel, a naturally occurring marvel, stands out significantly more than zinc when it comes to versatility and utility. Renowned for its magnetic allure, remarkable resistance to corrosion, and exceptional ductility, nickel carves a niche for itself in the world of elements.

Steel, a crucial alloy of iron and carbon, boasts remarkable tensile strength, robust corrosion resistance, and effective thermal conductivity. Its high yield strength and enduring durability make it a standout material. Galvanized steel, in particular, exhibits exceptional strength. The process of steel stamping is employed to craft a diverse array of products known for their high strength.

Brass, a lustrous blend of copper and zinc, boasts moderate resistance to corrosion and is not particularly strong. However, its visual appeal makes it a favorite for decorative purposes. Manufacturers often choose brass for creating ornate stampings, and it is widely used in the crafting of jewelry, plumbing, and household fixtures.

Aluminum metal is renowned for its softness, malleability, resistance to corrosion, electrical conductivity, thermal conductivity, and its nonmagnetic nature.

Copper, a natural element, boasts impressive electrical and thermal conductivity. Its pliability, malleability, and softness make it a favored ingredient in alloys. Ideal for shaping into large automotive components and deep-drawn metal stampings, copper also finds use in crafting expansive pots and pans.

Beryllium copper, the titan among copper alloys, stands unmatched in strength. Renowned for its formidable resistance to abrasive wear, galling, the breakdown products of plastics, and the assault of non-oxidizing acids, it boasts a suite of impressive attributes. Not only does it conduct electricity with grace, but it also excels in durability, welding, machining, and ductility, making it a versatile warrior in the world of metals.

Titanium is celebrated for its remarkable durability and impressive strength-to-weight ratio, along with its superior resistance to corrosion and inherent lightness. This metal is widely utilized in the form of stampings across the healthcare, defense, and aerospace sectors.

Process Details

The process of metal stamping typically unfolds with the help of several key components: a slide or ram, a press bed, and a stamping die or tool. Often, this process might involve multiple dies or punch presses. In essence, it can be distilled into a few straightforward steps.

- Insert sheet metal

To begin, manufacturers load the sheet metal onto the stationary press bed.

- Complete shaping operation

The die, ingeniously crafted with a bespoke cavity, meticulously sculpts metal parts from the introduced sheet metal. The upper segment of the die latches onto the press slide, orchestrating a rhythmic dance to and from the press bed, while its lower counterpart embraces the press bed itself. An additional element, known as the punch, plays a pivotal role in the symphony of shaping, as it propels the sheet metal through the die, finalizing the transformation.

Conduct secondary processes

Following their creation, the metal stampings typically undergo one or more supplementary processes.

For instance, plating enhances a component’s ability to resist corrosion, improves its solderability, and extends its durability. Popular materials used for plating include tin, nickel, gold, and palladium. Yet, if a manufacturer prefers to skip this step, they might choose to pre-plate the metal. Additional supplementary processes encompass heat treating, deburring, cleaning, and applying a powder coating.

Heat treating enhances hardness while reducing the risk of fractures.

Deburring smooths out sharp edges using abrasive materials or chemical processes.

Cleaning to eliminate residues and films left from the stamping process.

Powder coating adds a protective shield to the surface of the stamping.

Design

Before beginning a metal stamping project, manufacturers meticulously design the process to align with various application specifications. These specifications encompass the desired thickness and shape of the material, the size requirements, adherence to industry standards, necessary tolerances, and the essential or preferred characteristics of the material.

According to these guidelines, they can meticulously design their strategy, pinpointing the stamping technique to employ, the materials to choose, the die configuration, and any additional processes they will undertake. Given the inherently adaptable nature of stamping, manufacturers will effortlessly meet your specific custom metal stamping requirements.

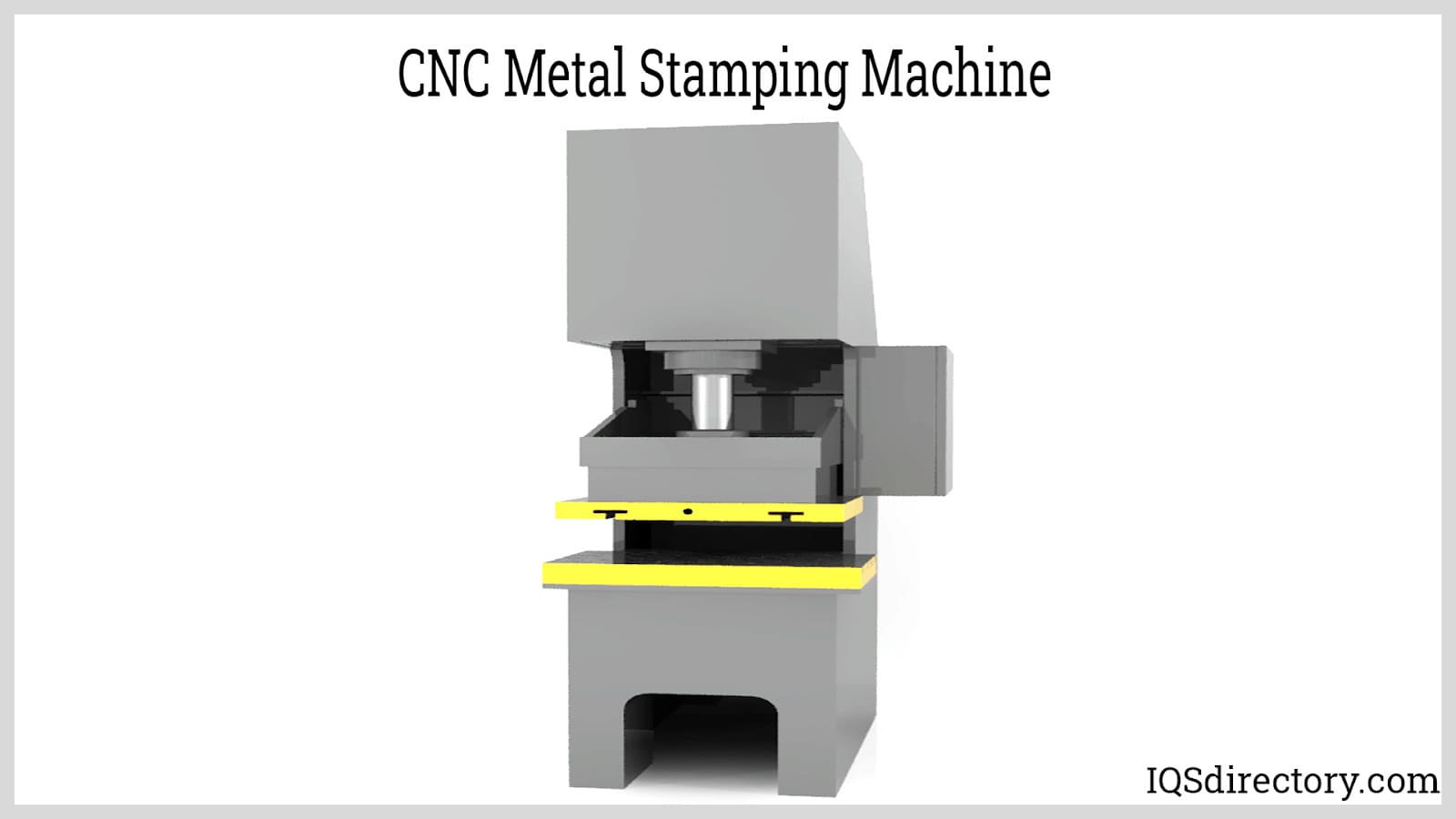

Machinery Used

Common types of stamp machines include mechanical, transfer, fourslide, and hydraulic presses.

Mechanical presses operate by harnessing energy generated in the flywheel, which is then conveyed to the electric shaft, eccentric gear, or crankshaft. A typical instance of such a press is the gear frame, a manually-operated, straight-frame press ideally suited for transfer die and progressive die tasks.

Transfer presses feature multiple stages through which components travel, yet unlike starting from a single piece or coil, the parts in transfer presses begin as distinct pieces of sheet metal.

Fourslide presses, aptly named for their quartet of slides, are marvels of automation in the pressing world. With this multi-directional capability, fourslide metal stampers deftly maneuver workpieces along both axes. This dual-axis versatility allows them to simultaneously shape, cut, and stamp materials, streamlining the production process with remarkable efficiency.

Hydraulic presses come in an array of frame styles such as straight sides, C-frames, four-column, and H-frames, each capable of exerting maximum force at any point during the stroke. This relentless power is driven by rams that follow a choreographed motion, propelled by the force of hydraulic pressure.

Hydraulic presses excel in tasks requiring precision metal stampings, accommodate both short runs and deep drawing, and are ideal for high-tonnage blanking at lower speeds with extended feeds, ensuring consistent pressure throughout. They come in an extensive array of tonnage capacities, sizes, operating speeds, and stroke lengths, making them versatile for a myriad of stamping needs and processes.

Variations and Similar Processes

Manufacturers can choose from a variety of stamping processes, including progressive stamping, transfer die stamping, line die stamping, and compound die stamping.

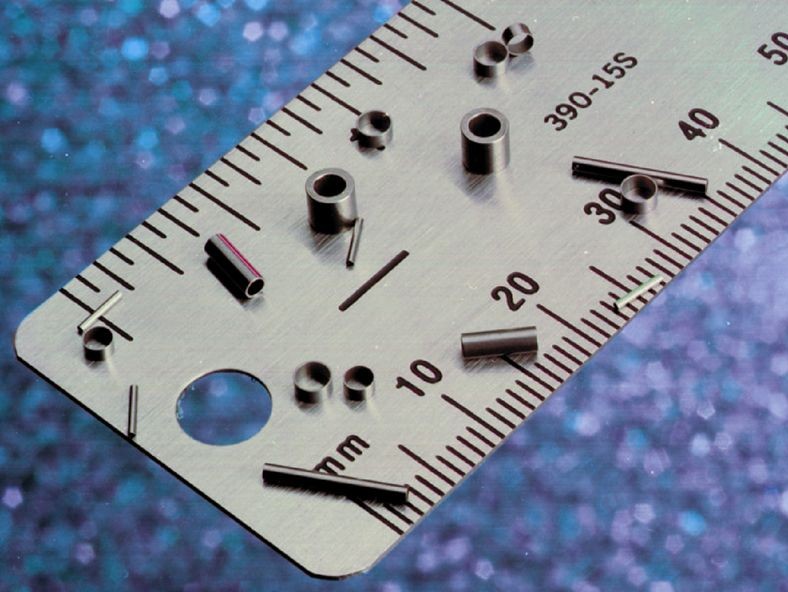

Progressive stamping, often referred to as the progressive die method, unfolds as a seamless, ongoing procedure tailored for crafting small, precision components such as medical and electronic stampings, along with metal clips, brackets, and spring clips. This method leverages a continuous production cycle, enabling the creation of high volumes of stampings in a remarkably short timeframe. Indeed, progressive stamping stands as the most rapid technique for fabricating metal stampings.

Transfer die stamping is a method of creating stamps where the sheet metal is in motion, unlike traditional methods where it remains fixed. Equipped with various tools, transfer stamping presses multitask by shifting the metal workpiece from one station to another, typically along automated rails. All these activities unfold within a single press, which can be custom-programmed to suit specific operations.

Line die stamping is a manufacturing technique that allows the efficient and cost-effective production of large components. Line dies may be loaded either by robots or manually. While robotic loading is favored for its safety and efficiency, manual loading is sometimes necessary for especially large parts or during smaller production runs.

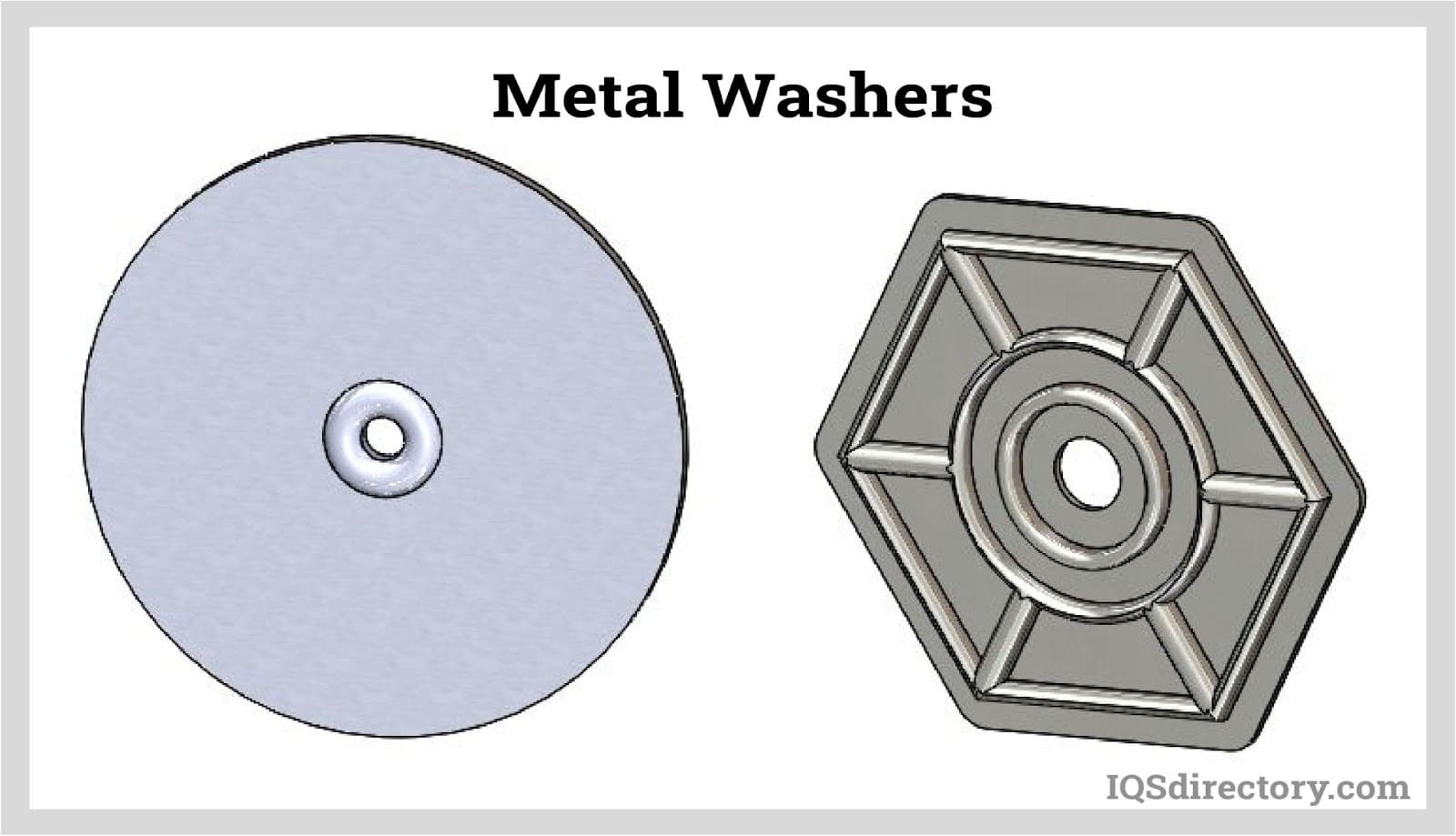

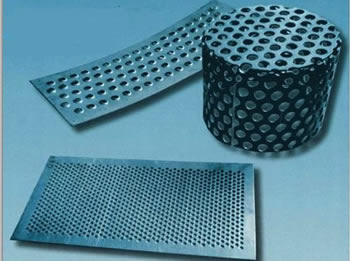

Compound die stamping slices through steel strips in a single, swift motion, separating the workpiece cleanly from its origin. Within this singular stroke, the die is capable of executing multiple punches and cuts simultaneously. This method is particularly favored for crafting straightforward metal hardware such as washers, offering an economical solution for producing medium to high volumes efficiently.

Benefits

Investing in metal stamping is a wise decision. Why? For starters, the process yields parts with remarkable precision, uniformity, and the ability to meet exacting tolerances. Moreover, the cost of tooling for metal stamping is notably lower compared to other manufacturing techniques such as molding, forging, casting, and expendable cutting tools. Metal stamping also excels in crafting robust components from tougher materials that other methods might not accommodate. To explore the full spectrum of opportunities metal stamping offers, consider reaching out to a stamp service provider.

Finding the Right Manufacturer

In your quest for top-tier metal stamping, entrust your needs to a proven, reputable firm. The industry is currently experiencing a surge, bringing a plethora of players into the market—some seasoned, others not so reliable, enticed by the promise of cut-rate prices. To navigate this crowded field, we’ve curated a select list of trusted, veteran metal stampers. Detailed profiles of these artisans are scattered across this page. When you’re poised to delve deeper, allocate time to pore over these profiles. Select three or four candidates that resonate with your project’s unique requirements. Initiate discussions with these chosen few, exploring everything from your basic needs and bespoke demands to budget constraints, timelines, delivery logistics, and the scope of support after completion. Post-discussion, weigh your options by comparing these engagements. Pinpoint the manufacturer that not only promises the best value, including exclusive gold member perks, but also stands out for product excellence and customer service. Reach out once more to kickstart your project.

Check out our Aluminum Extrusions website

Check out our Wire Rope website

What processes are involved in metal stamping?

Metal stamping involves various metalworking techniques using a press machine, such as bending, blanking, coining, embossing, flanging, forging, and punching to shape metal sheets into desired forms.

In which industries are metal stampings commonly used?

Metal stampings are used in a wide variety of industries including automotive, electronics, aerospace, and consumer goods. They are essential for manufacturing components such as body panels, brackets, engine parts, connectors, terminals, and decorative elements.

What materials can be used in metal stamping?

A broad range of materials are suitable for metal stamping, including zinc, nickel, steel, brass, aluminum, copper, titanium, and various alloys. Each material offers specific benefits based on strength, corrosion resistance, conductivity, and other properties.

What are the typical steps in the metal stamping process?

The metal stamping process generally includes inserting sheet metal onto a press bed, shaping the metal using a die, and performing secondary processes such as plating, heat treating, deburring, cleaning, and powder coating to enhance the part’s performance and durability.

What types of machinery are used in metal stamping?

Metal stamping operations utilize various presses including mechanical, transfer, fourslide, and hydraulic presses. Each machine type offers distinct advantages in terms of automation, precision, and capacity, making them suitable for different applications and production volumes.

What are some variations of metal stamping processes?

Common variations include progressive stamping, transfer die stamping, line die stamping, and compound die stamping. Each method offers unique benefits, such as increased speed, ability to perform multiple operations in one press, or cost efficiency for specific part types and production volumes.

What are the benefits of metal stamping compared to other manufacturing processes?

Metal stamping offers high precision, uniformity, and the ability to meet tight tolerances. The tooling costs are typically lower than for molding or casting, and the process is well-suited for producing robust parts from strong materials with efficiency and cost-effectiveness.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services