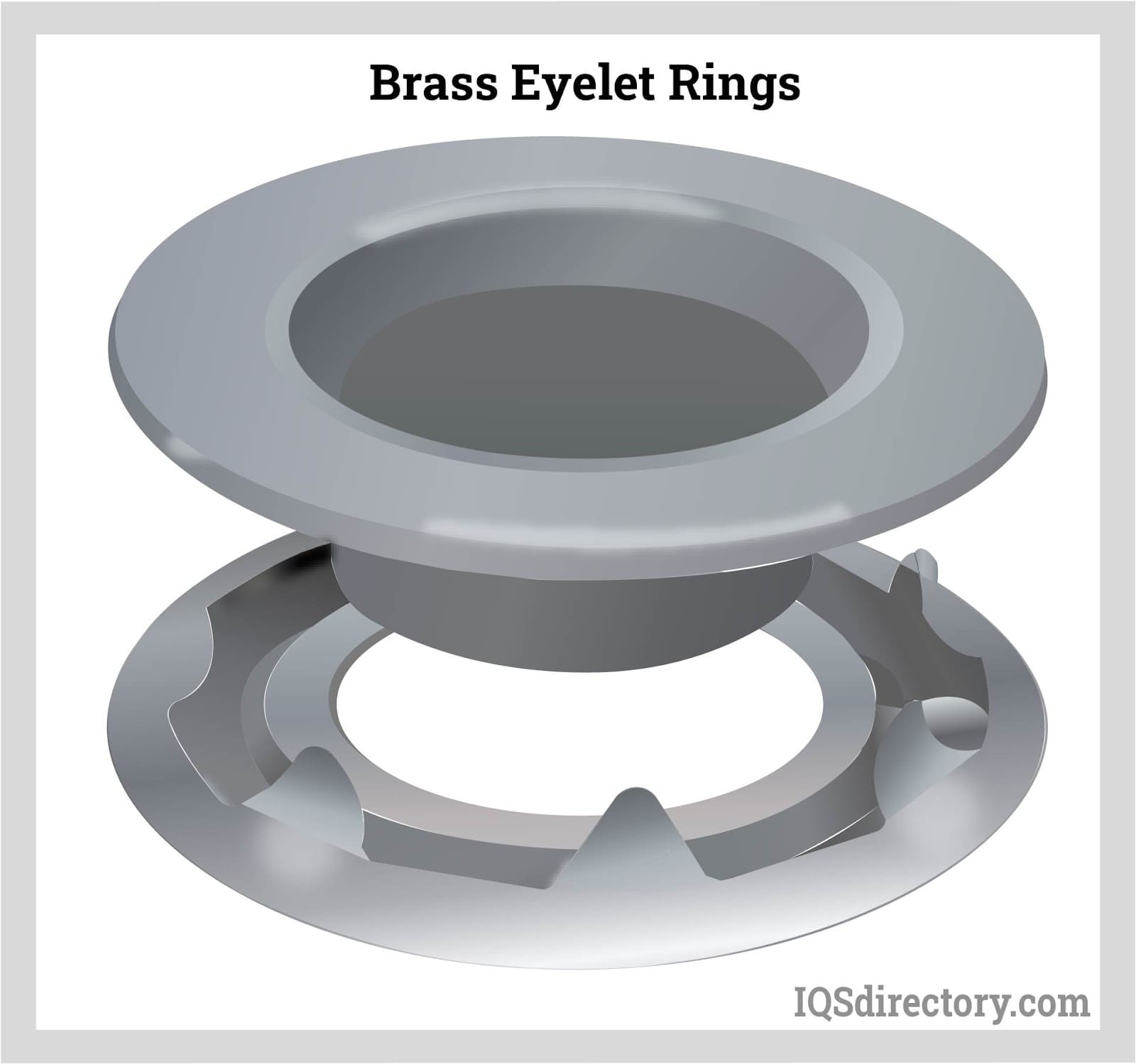

Brass (a copper and zinc alloy) custom metal stampings are frequently utilized for decorative products. Most brass grades may be deep-drawn, shaped, and easily perforated. Brass varies in terms of electrical conductivity, corrosion resistance, surface smoothness, and reaction to chemicals, heat, and plating according to the grade used. Numerous businesses will use brass metal stampings when the cosmetic appearance of the stamping is crucial. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

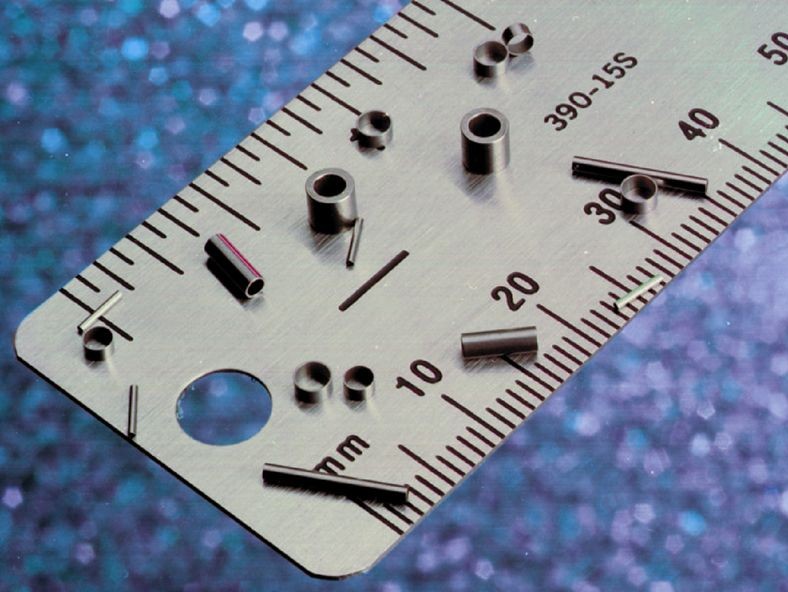

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

CSS is a leading international manufacturer of precision springs and metal shaped components. We have been a strategic supplier of progressive stampings, fineblanked stampings, machined stampings, springs and assemblies for 86 years. CSS serves OEMs in a wide variety of industries including medical, aerospace, defense/firearms, automotive, electronics and consumer products.

At Acorn Stamping, we specialize in precision metal stamping that meets the highest standards of accuracy, repeatability, and performance. With decades of experience and a deep understanding of material behavior, we deliver stamped components that serve a wide range of industries, including automotive, electronics, and industrial manufacturing.

More Brass Stamping Companies

This application is particularly true in the commercial and residential door hardware industry. Brass is impervious to most common conditions except prolonged exterior exposure and abrasion. When low friction and the avoidance of sparks are necessary, brass is also employed in metal stampings; as a result, a lot of brass metal stampings are used in electrical applications, as well as heavy artillery and ammunition casings.

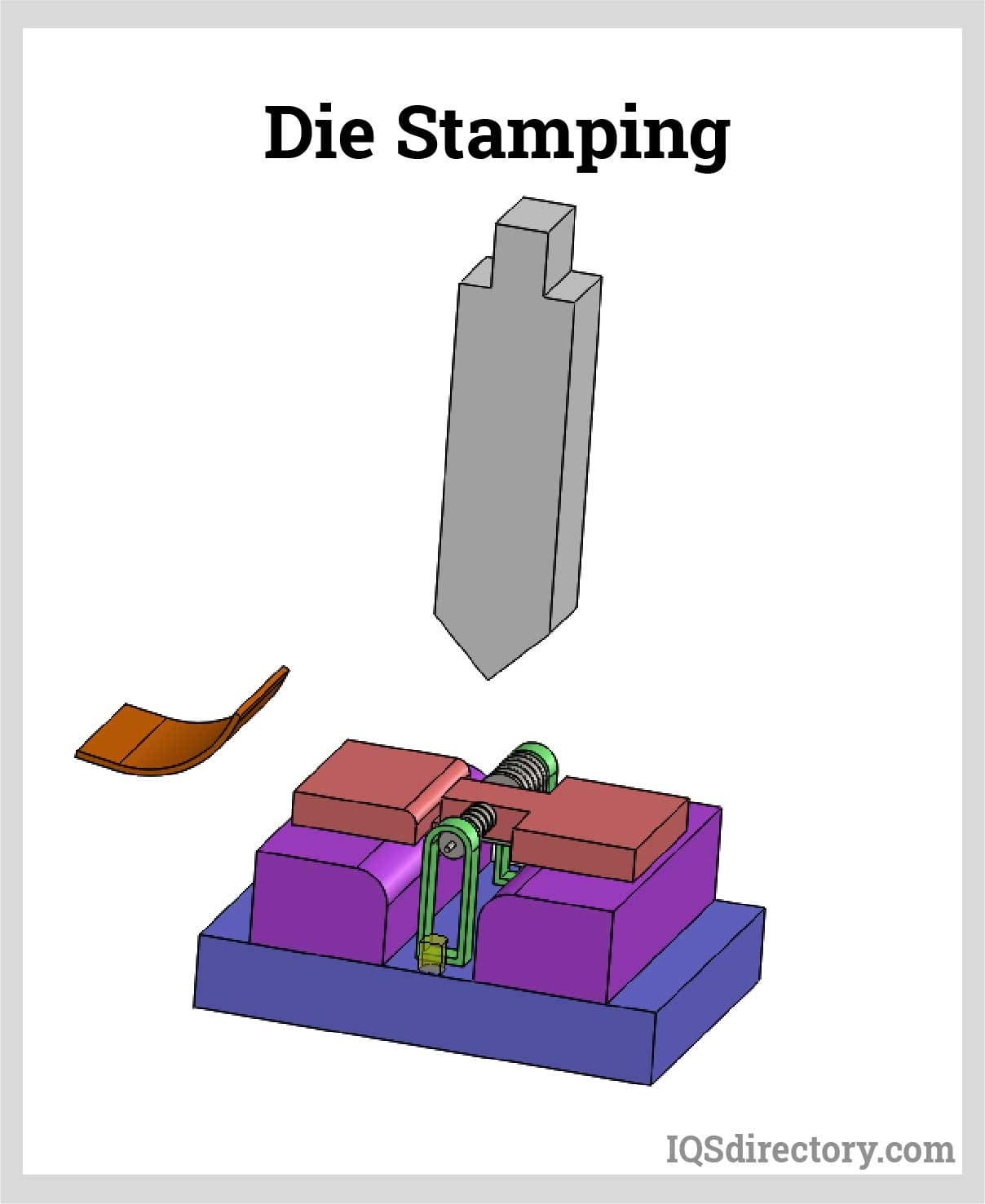

A flat brass sheet is fed into a stamping press during the brass stamping procedure, also known as brass pressing. The brass is then shaped into the desired shape by this press using pressure and a die. The following are a few examples of stamping methods: punching, coining, embossing, bending, blanking, and flanging.

Types of Techniques Used in Brass Stamping

Various brass stamping techniques are used for certain applications, as described below.

Progressive Die Stamping

This stamping method divides the procedure into several stations, each performing a separate task. First, the part is transported down the stock strip from one station to the next until it is finished and taken off. Next, the original brass strip is transported to the die press from its coil. The piece then travels horizontally via each station. Finally, the part proceeds to the following station until it has undergone the necessary bend, punch, or cut. Each movement must be as precise as possible because the part is still attached to the strip while it is being changed. This accuracy and precision ensure that the final component is precise and functional.

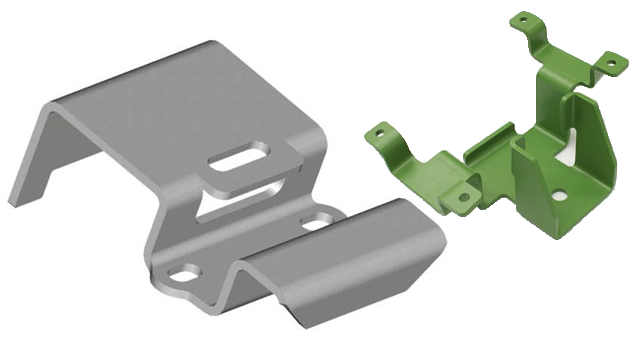

Transfer Die Stamping

Transfer die stamping is yet another variety of stamping. Unlike progressive die stamping, a mechanical transport system moves the part instead of an automated strip from station to station. Making pieces that need to be separated from the metal strip during the stamping process uses this sort of stamping.

One die may be used for this on its own, or a manufacturing line may have several dies or equipment lined up in a row. Transfer die stamping is a great alternative for production because of the cheaper tooling costs. They can also create features like cut-outs, ribs, knurls, threading, and piercing holes. They are extremely adaptable. This adaptability eliminates the need for any additional procedures, thus reducing costs. Transfer die stamping is employed in various industries, including agriculture, transportation, electronics, medicine, and recreational vehicles. It helps produce bigger, bulkier items that might need to go through several presses.

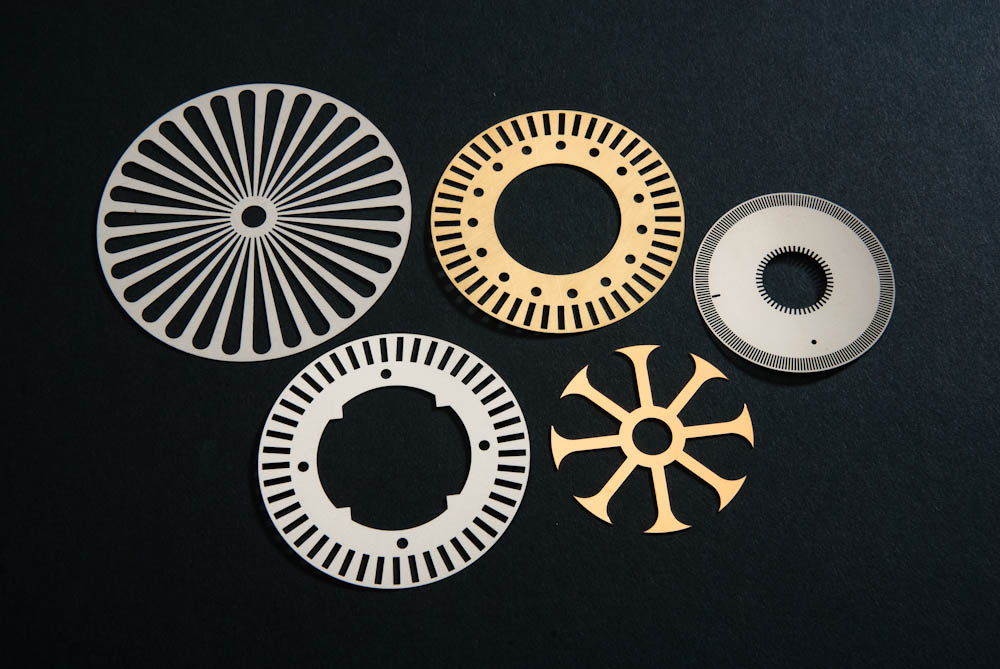

Fine Blanking

Fine blanking, also known as fine-edge blanking, is an additional type of brass stamping. In a way that other metal stamping procedures cannot, this specialized metal stamping is perfect for creating flatness and a fully sheared edge. This method uses cold extrusion and only requires one step, which lowers the cost of manufacture. Typically, a hydraulic, mechanical, or a mix of the two presses is used for fine blanking. Three different motions are employed in the fine blanking procedure:

- Placing the workpiece or work material in place using the clamp on the workpiece

- Finishing the blanking process

- Expelling he completed component

The manufactured item must make full contact with the surface on the edge of the portion to be functional. Gears are one type of component that frequently uses fine blanking. Fine blanking is the ideal method for this production since gears need to be flat in specific places and fully engaged on all teeth to function. In addition, compared to more traditional stamping procedures, the machinery needs to be built to handle the significantly higher pressures used by the fine blanking press.

Four-Slide Stamping

Four tools are used simultaneously in four-slide stamping, also known as multi-slide stamping, to mold the component into the desired shape. Each shaft quickly bends the metal sheet as it is fed through the four slides. It is perfect for making things that need complex bends or intricate cuts. Four-slide stamping shapes the metal piece using four sliding tools, as opposed to other metal stamping methods that use a vertical slide during production.

Four-slide stamping is a great way to make complex or multi-part bends, even larger than 90 degrees because the tool slides are simple and very productive. It is possible to execute several bends, punches, folds, or cuts in a single motion. Four-slide stamping also has the benefit of having relatively affordable tooling and little waste generated during production.

Benefits of Brass Stamping

- Stamping is inexpensive when compared to other stamping techniques.

- A higher degree of automation than other presses

- Less expensive to create or maintain than those employed in other methods

- Lower-cost ancillary expenses like plating or cleaning

- Can deliver enhanced precision using highly specialized computer programs

- Metal stamping often has faster production and turnaround times.

- The ability to automate this procedure results in low labor costs.

Disadvantages of Brass Stamping

- It's not always simple or quick to obtain the dies required in metal stamping.

- The presses themselves are quite expensive and difficult to transport. In addition, pre-production takes longer when specialized dies are utilized.

- It can be challenging to do if dies need to be altered mid-production due to a change in design.

Choosing the Right Brass Stampings Manufacturer

To make sure you have the most productive outcome when purchasing Brass Stampings from a Brass Stampings Manufacturer, it is important to compare at least 4 or 5 Companies using our list of Brass Stampings manufacturers. Each Brass Stampings Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Brass Stampings company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Brass Stampings companies with the same message.

Broaching

Broaching CNC Machining

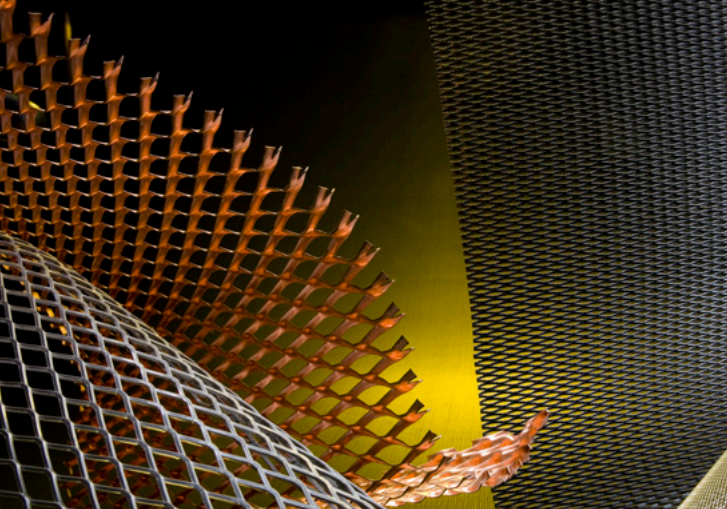

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

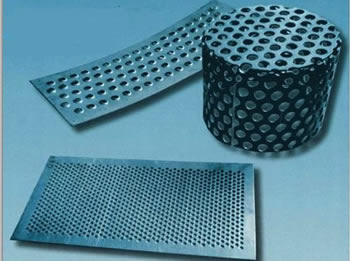

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services