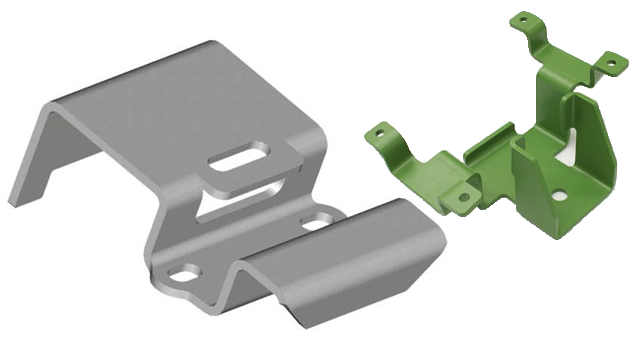

Deep drawn stamping is used to create incredibly complicated pieces by combining flanging, bulging, flaring, and necking with other stamping and shaping techniques. A flat blanking strip that has been punched into numerous open hollow pieces or has had its diameter reduced and height increased is processed using a deep-drawn stamping technique. Cylindrical, stepped, tapered, spherical, box-shaped, and other irregularly shaped thin-walled parts can be produced using the deep-drawing method. The deep drawing process is crucial in producing components for the automotive, aircraft, medical, electrical, instrument, and electronic industries. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

CSS is a leading international manufacturer of precision springs and metal shaped components. We have been a strategic supplier of progressive stampings, fineblanked stampings, machined stampings, springs and assemblies for 86 years. CSS serves OEMs in a wide variety of industries including medical, aerospace, defense/firearms, automotive, electronics and consumer products.

At Acorn Stamping, we specialize in precision metal stamping that meets the highest standards of accuracy, repeatability, and performance. With decades of experience and a deep understanding of material behavior, we deliver stamped components that serve a wide range of industries, including automotive, electronics, and industrial manufacturing.

More Deep Drawn Stamping Companies

Deep Drawing Stamping

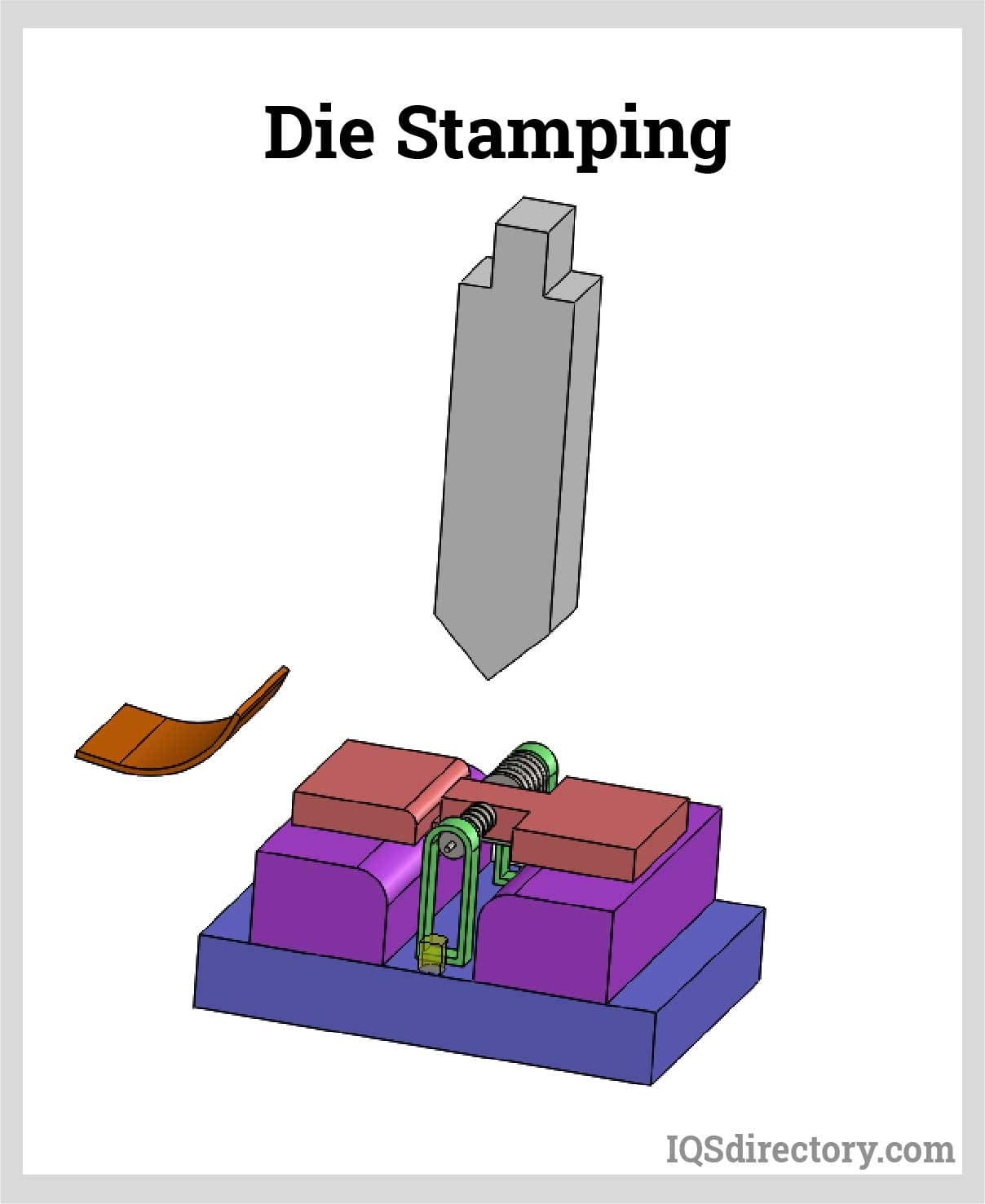

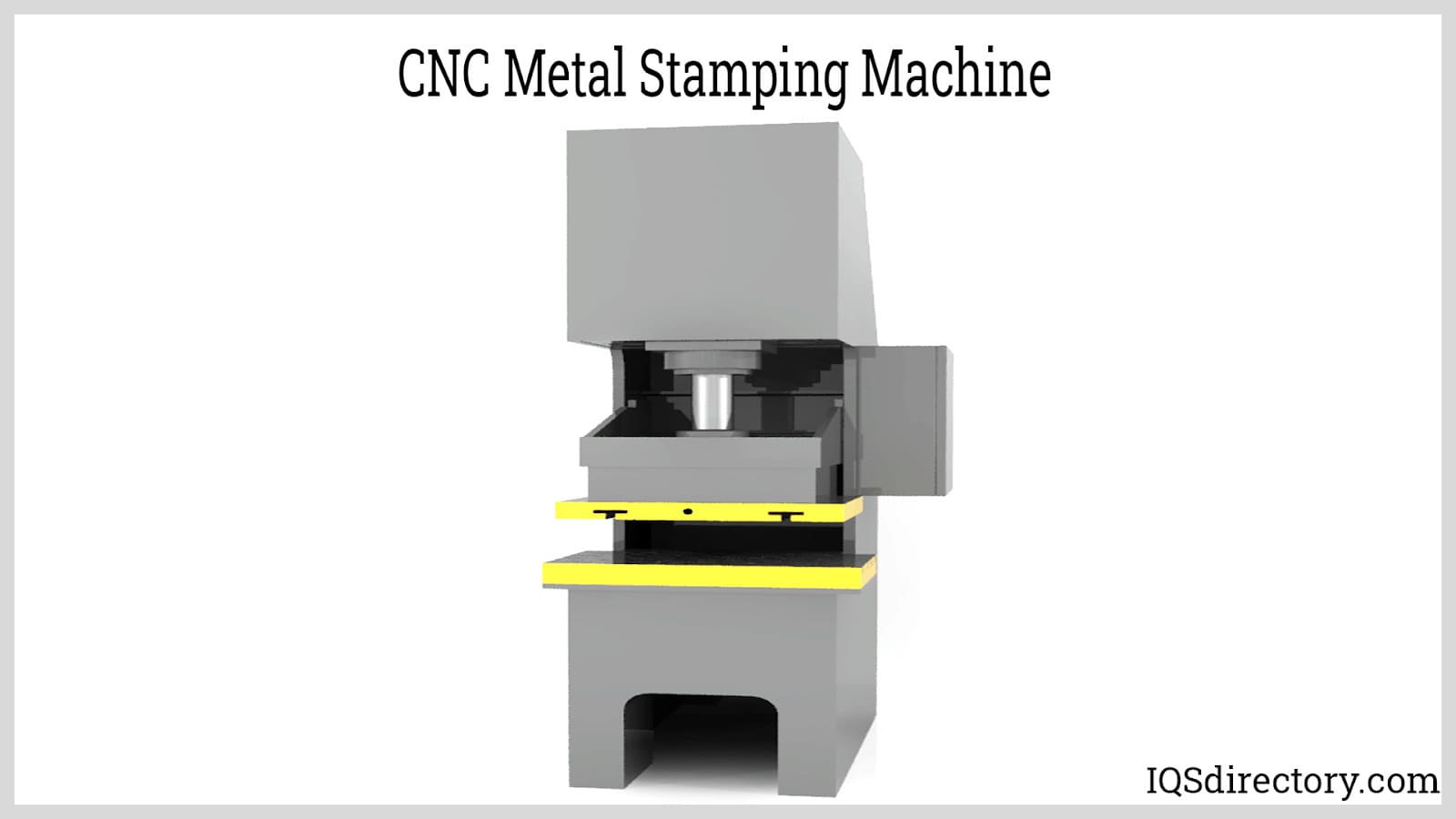

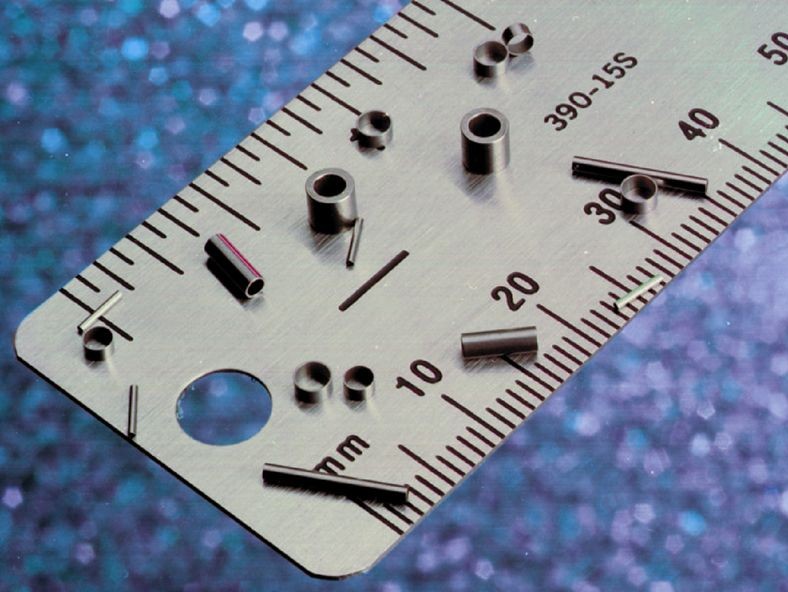

Cold-forming technique known as metal stamping, sometimes known as metal pressing, is used to create a variety of parts and goods from coil strip metal. It is often carried out with materials at room temperature because it is a cold working procedure. For various industries, stamped components come in various sizes and shapes, with simple pieces ranging from 0.08 - 2.0 inches in diameter and up to 3.0 inches in length.

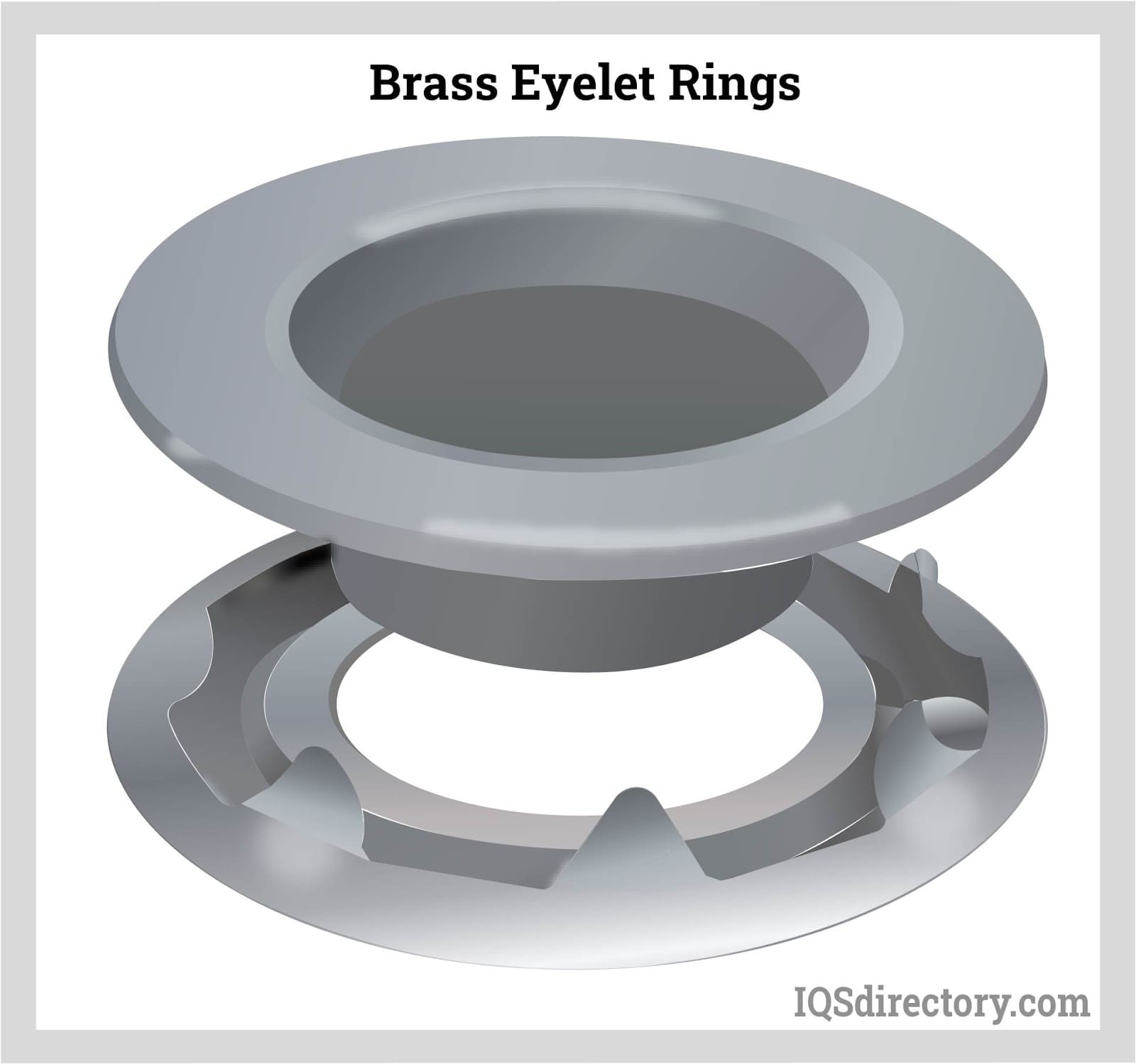

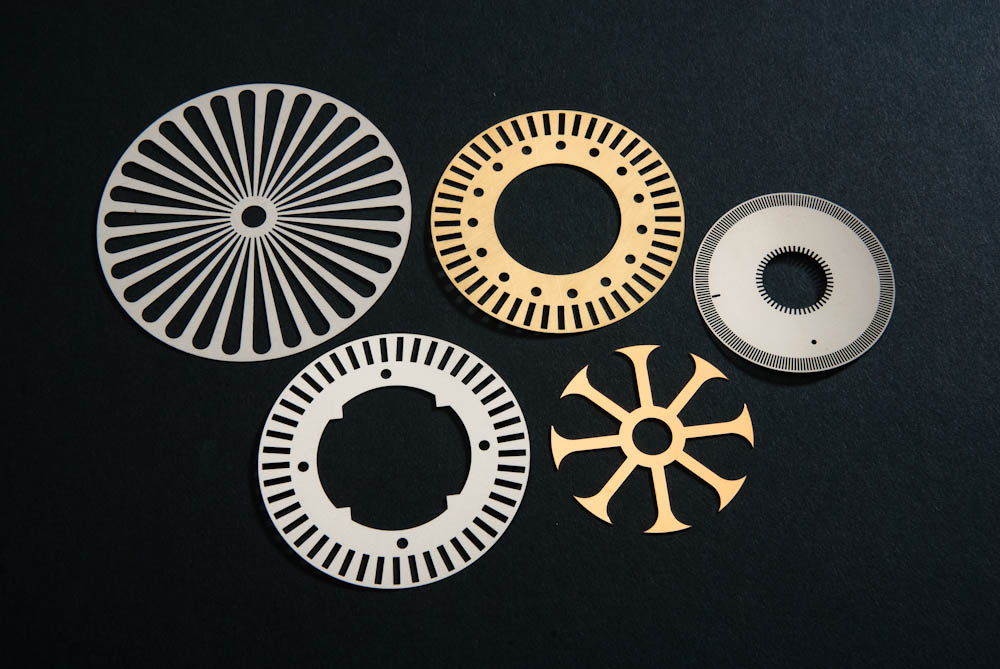

Deep drawing is a type of metal stamping that creates seamless round enclosures (i.e., cases) that are at least as high (or taller) as they are wide. It is also known as deep drawn or deep draw stamping. Cans, housings, and other containers are common deep-drawn components. They work especially effectively in harsh conditions where precision is essential, like the electronic industry.

Deep Drawn Stamping Process

The deep drawn stamping process uses radial tension and tangential pressure to shape and size metal. Then, according to the part design, a sequence of specialized dies and punches reduce the blank's diameter and lengthen the flat metal disc. The final product has cylindrical or hollow sides that might be straight, tapered or a combination of both.

The following procedures are part of a deep-drawn stamping operation standard:

Determining the material: They decide which material best suits the part and manufacturing requirements. Deep-drawn stamping commonly uses aluminum, brass, copper, stainless steel, low-carbon steel, and other materials.

The stamping process: After deciding on the design and material, manufacturers can proceed to the stamping stage. First, they gradually shape the blank into the part using the press and tooling (i.e., punches and dies) they identified during the design step. A single item requires five or more stations to obtain the desired shape and size. Each station, i.e., draw or reduction, reduces the diameter and increases the height of the material. The kind and thickness of the stamping material and the part design determine how many draws or reductions are necessary.

Advantages of Deep Drawing Stamping

Deep-drawn stamping is a manufacturing process that has various benefits for specialists in the field. Although it might not be the best option for every part or manufacturing necessity, it does offer certain following advantages:

High accuracy and tight tolerances: Deep-drawn stamping is a highly reproducible and accurate procedure.

Few process steps: Deep-drawn pieces can be produced with fewer operations because they don't need to be trimmed or put together. Additionally, they demand less manual work because of their high precision, ability to accommodate automation, and other quick manufacturing techniques.

Fast process speeds: Punch presses often provide the quickest processing speeds compared to other industrial machinery. This quality can produce a single part or product in vast quantities.

Large production volumes: Deep-drawn stamping is perfect for tasks requiring high manufacturing volumes. Once the dies and punches are prepared, the presses can constantly run at high speeds with little downtime or operator intervention.

Low production costs: While the tooling for a deep-drawn stamping may require a sizable initial investment, operations can continue with little downtime or additional equipment expenditures after it is purchased or developed.

Seamless parts: Deep drawing uses a single blank that isn't sliced or welded to create its parts. The end product is a water or air-tight component with no seams or connected edges.

High hardness and strength: Metals undergo work hardening when they are deeply drawn for stamping. This process produces exceptionally strong and durable pieces with little mobility in the crystalline structure.

Processes to Compliment Deep Drawn Stamping

Deep-drawn stamping operations frequently integrate other shaping and finishing procedures to produce more complex, completed parts and products. A few of the techniques are listed here:

Bulging: The walls of a part are expanded during the bulging process using specialized expansion punches. The expansion can create symmetrical or asymmetrical shapes by focusing on the entire object or a specific area.

Coining: To generate delicate features with precise tolerances, the coining process uses closed dies that contain or limit the entire object.

Curling: The workpiece's open end has a rolled edge created by the curling process.

Dimpling: Dimpling leaves a mark on the workpiece that can be used for subsequent flush riveting or bolting operations.

Embossing: Raised or depressed patterns are produced on the metal during the embossing process.

Extruding: The method of extrusion, also known as hole flanging, involves drawing a flange around a hole in the object.

Hole forming: Traditional, extruding, and piercing punches can create holes.

Ironing: The walls of the part are thinned and have their surface smoothed during the ironing process.

Marking: The marking procedure adds distinguishing elements to the workpiece, such as patterns, numbers, or words.

Necking: The diameter of one particular portion of a cylindrical workpiece is decreased during the necking process.

Notching: Cuts, or notches, are made along the edge of the workpiece during the notching process to accommodate upcoming mounting or clearance requirements.

Threading: Threads are made along a section of the part using taps, dies, or a wheel and arbor set.

Trimming: Trimming removes waste material from a partially or finished item.

Choosing the Proper Deep Drawn Stamping Supplier

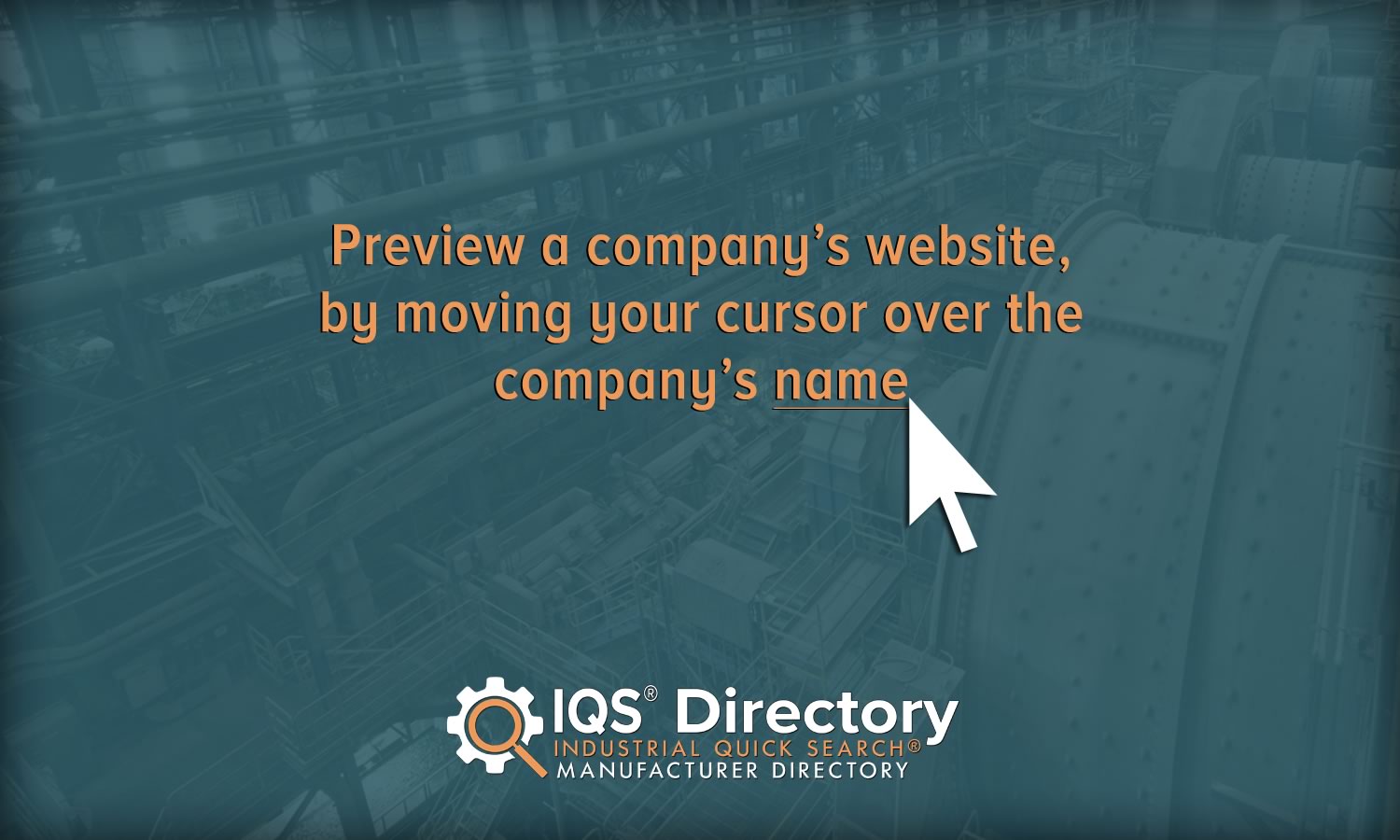

To make sure you have the most productive outcome when purchasing Deep Drawn Stamping from a Deep Drawn Stamping Supplier, it is important to compare at least 4 Companies using our Deep Drawn Stamping directory. Each Deep Drawn Stamping Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Deep Drawn Stamping business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Deep Drawn Stamping businesses with the same quote.

Broaching

Broaching CNC Machining

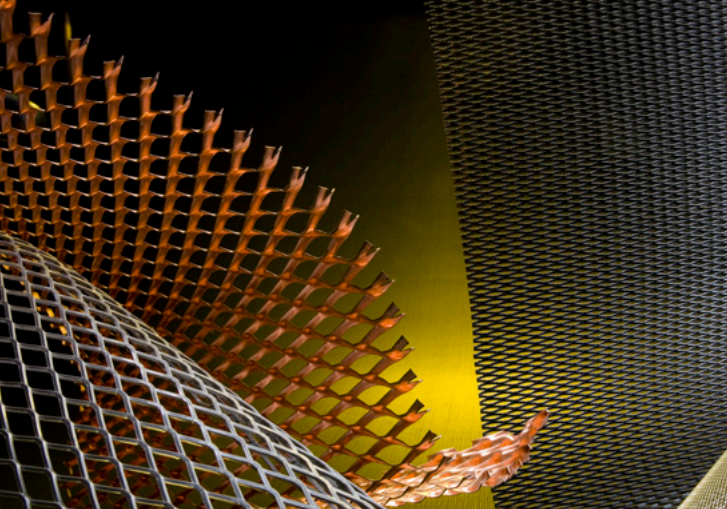

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

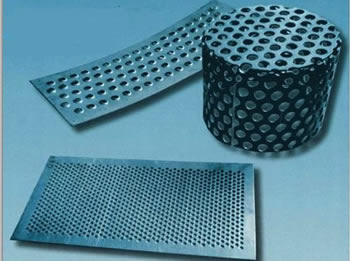

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

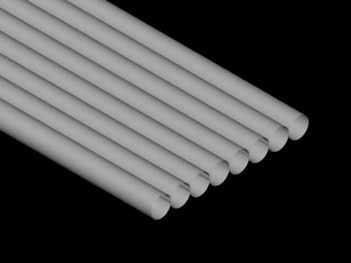

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services