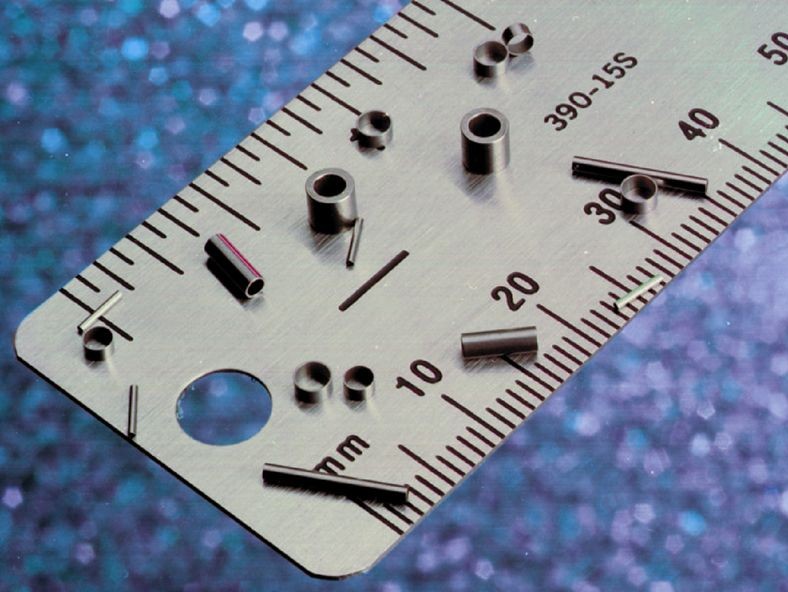

Ferrules are defined as any ring used to reinforce a shaft or bring material strands together. A ferrule is generally a small, deformable tube made of tin-plated copper in the context of wiring. A great benefit to ferrules is that they minimize the contact resistance between the connector and the wire. Ferrules also help in reduction. Ferrules are available in different and various colors, depending on the wire that requires it to be crimped. Read More…

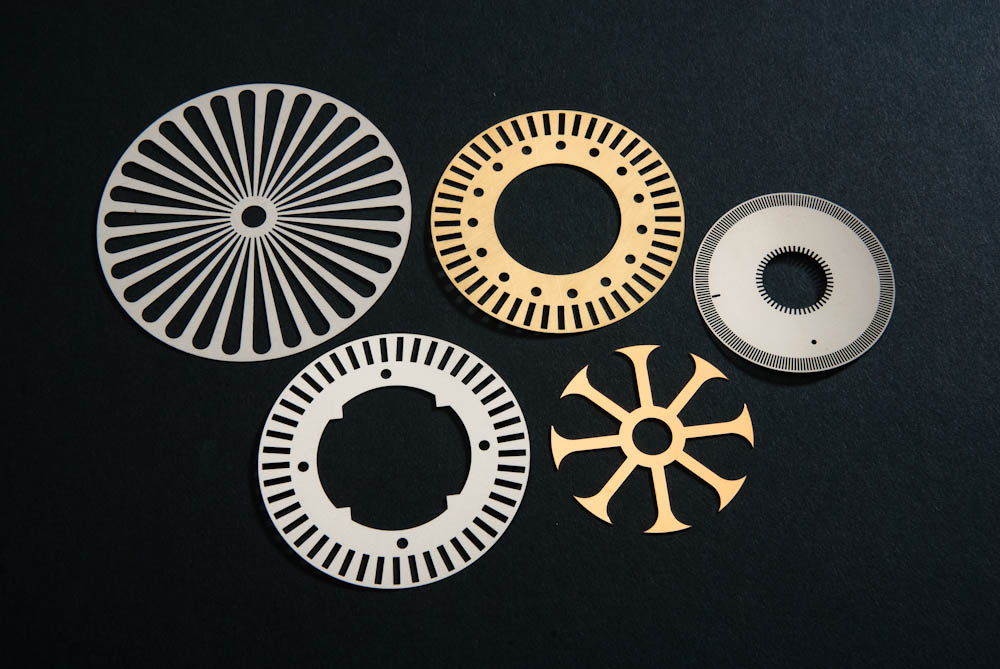

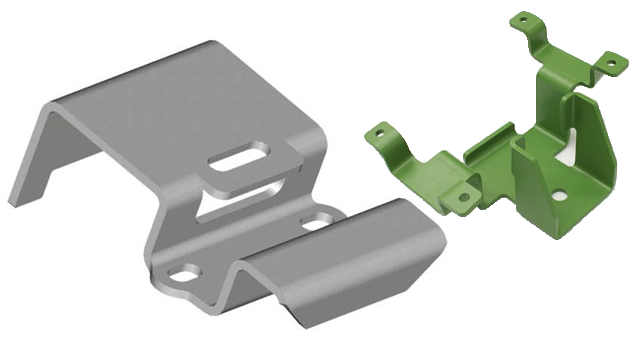

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

CSS is a leading international manufacturer of precision springs and metal shaped components. We have been a strategic supplier of progressive stampings, fineblanked stampings, machined stampings, springs and assemblies for 86 years. CSS serves OEMs in a wide variety of industries including medical, aerospace, defense/firearms, automotive, electronics and consumer products.

At Acorn Stamping, we specialize in precision metal stamping that meets the highest standards of accuracy, repeatability, and performance. With decades of experience and a deep understanding of material behavior, we deliver stamped components that serve a wide range of industries, including automotive, electronics, and industrial manufacturing.

More Ferrule Companies

Construction of a Ferrule

The construction of a ferrule is a very simple process. The metal part is made up of copper and covered with tin. The sleeve is of PVC material or polyamide. Proper caution should be taken with its diameters. Usually, the ferrule is matched to the cable cross-section where it will be connected. For example, a 2.5 ferrule will have to be connected to a cable that is 2.5 mm^2.

How Ferrules Function

Most ferrules are made up of a circular clamp used to attach and hold together posts, fibers, or wires, generally by crimping, swaging, or deforming the ferrule. This will permanently tighten the ferrule onto the parts that need to be held. As the ferrule is driven axially into the fitting body, radial compression of the body's angled shape occurs, thereby pushing the end part of the ferrule onto the tubing's outer diameter.

- Cross-section of the cable

- Color

- Ferrule dimensions

- Structure of the header

- Cable stripping length

- Single or double connection

- International standards

Types of Ferrules

Various categories of ferrules are available in the electrical marketplace. However, there is a wide range of ferrules that are different from others and perform different purposes. Wire ferrules are those in the form of a pin terminal used to stop the unraveling of the stranded wire and maximize the electrical connection stability. They ensure safe and reliable connections and minimize the breakage caused by bending, vibration, or wire stress. Wire ferrules facilitate the insertion of the wire inside a terminal clamp. There are four types of ferrules: twin, insulated, single, and non-insulated.

Insulated Ferrule

The insulated ferrule consists of a sleeve which is plastic colored over a copper tube which is tin plated. Insulated wire ferrules allow for the visual color designation of the wire sizes. This will help in the quality inspection and identification. The insulated wire ferrule is much easier to work with, especially when working with smaller conductors. The ferrule offers and ensures a reliable connection. They can be made use in any type of application.

Uninsulated Ferrule

An uninsulated ferrule does not consist of a plastic sleeve. Its function is to prevent wire strands from breaking and fraying. Uninsulated ferrules are cost-effective and have a shorter length and uninsulated body. They offer many benefits when terminating in terminal blocks with narrow widths or smaller clamps and in printed circuit board terminal blocks.

Single Ferrule

A single ferrule is available in an insulated or uninsulated form. They can be crimped to one single cable. A single ferrule fitting consists of a single ferrule that grips the tubing and forms a leak-tight seal between the fitting body and the compression nut. In such a scenario, the single ferrule has two functions: sealing the fitting and locking it in its place.

Twin Ferrule

A twin ferrule can be crimped into two cables. Its diameters are larger, and it consists of specially-shaped sleeves that can take in two conductors that have different or the same size.This ferrule provides an efficient connection of multiple wires in one terminal clamp.

Applications and Advantages of Ferrules

The applications and advantages of ferrules include:

Applications of Ferrules

- Reinforcing of shafts

- Marine purposes

- Concrete strap loops

- Binding material strands together

- Securing strands within a terminal

Advantages of Using Ferrules

- Ferrules can maximize the overall safety of any wiring.

- They can give more consistency as compared to traditional wiring methods.

- Ferrules provide a clean and safe method for connecting many wires to one point.

- Ferrules are versatile and have a wide range of varieties.

- Ferrules can meet most applications' needs.

- They tend to increase the quality of the work provided.

Choosing the Right Ferrules Supplier

To make sure you have the most beneficial outcome when purchasing Ferrules from a Ferrules Supplier, it is important to compare at least 6 Suppliers using our list of Ferrules manufacturers. Each Ferrules Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Ferrules company website using our {patented/proprietary} website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Ferrules businesses with the same message.

Broaching

Broaching CNC Machining

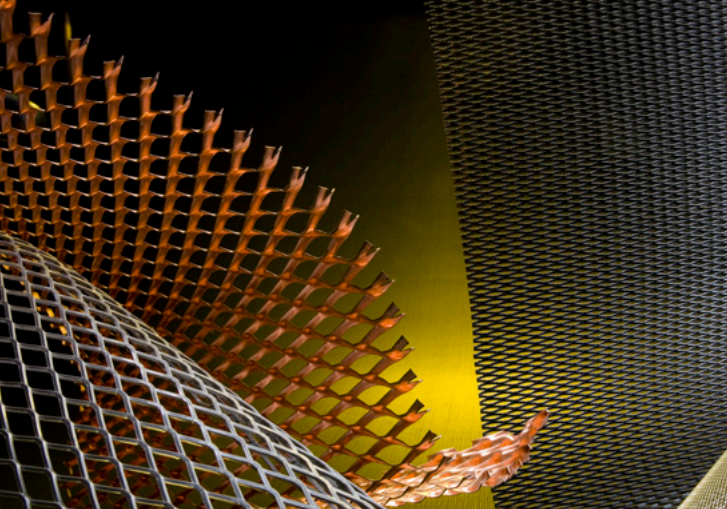

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

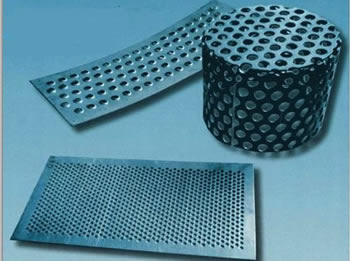

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services