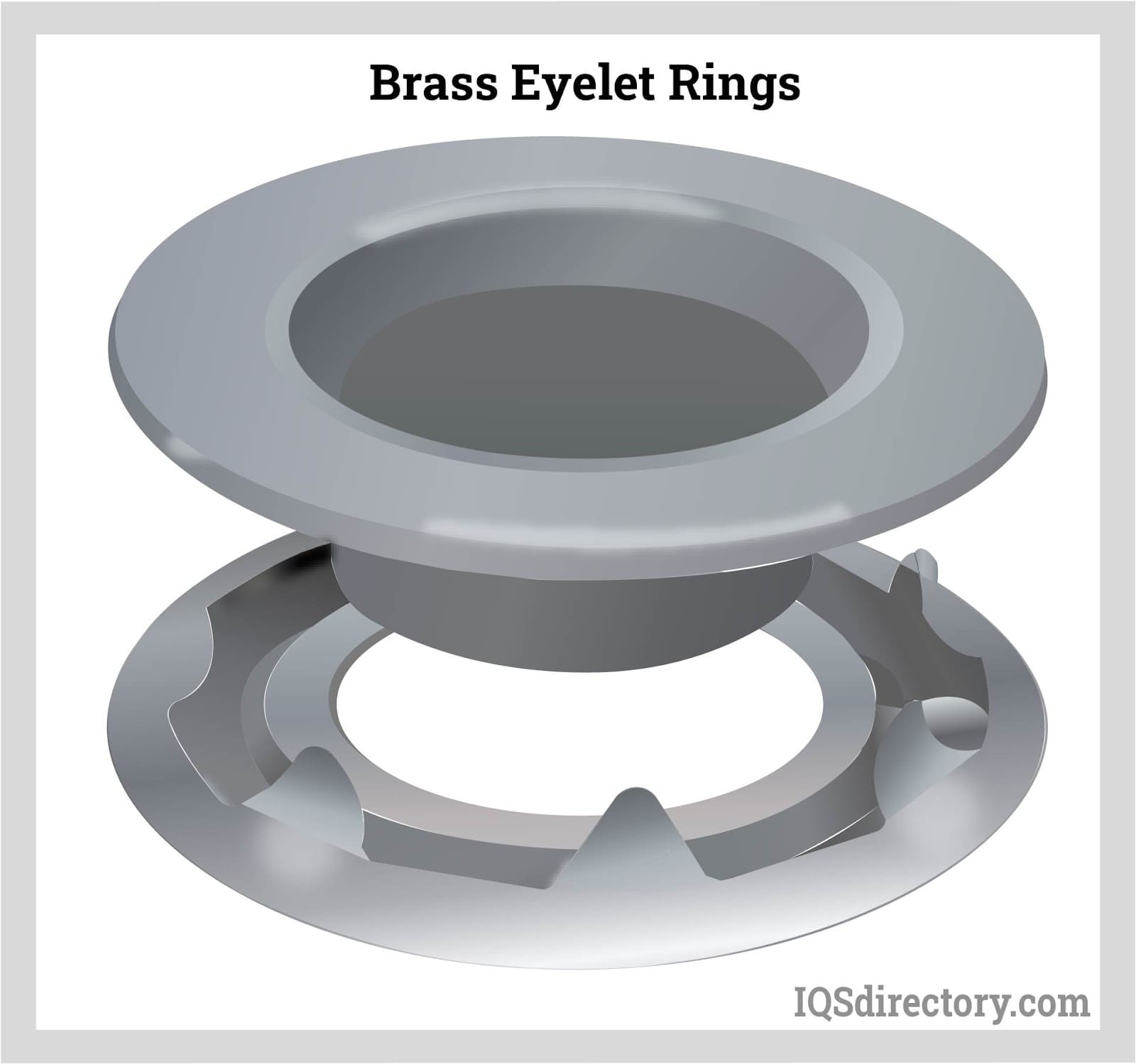

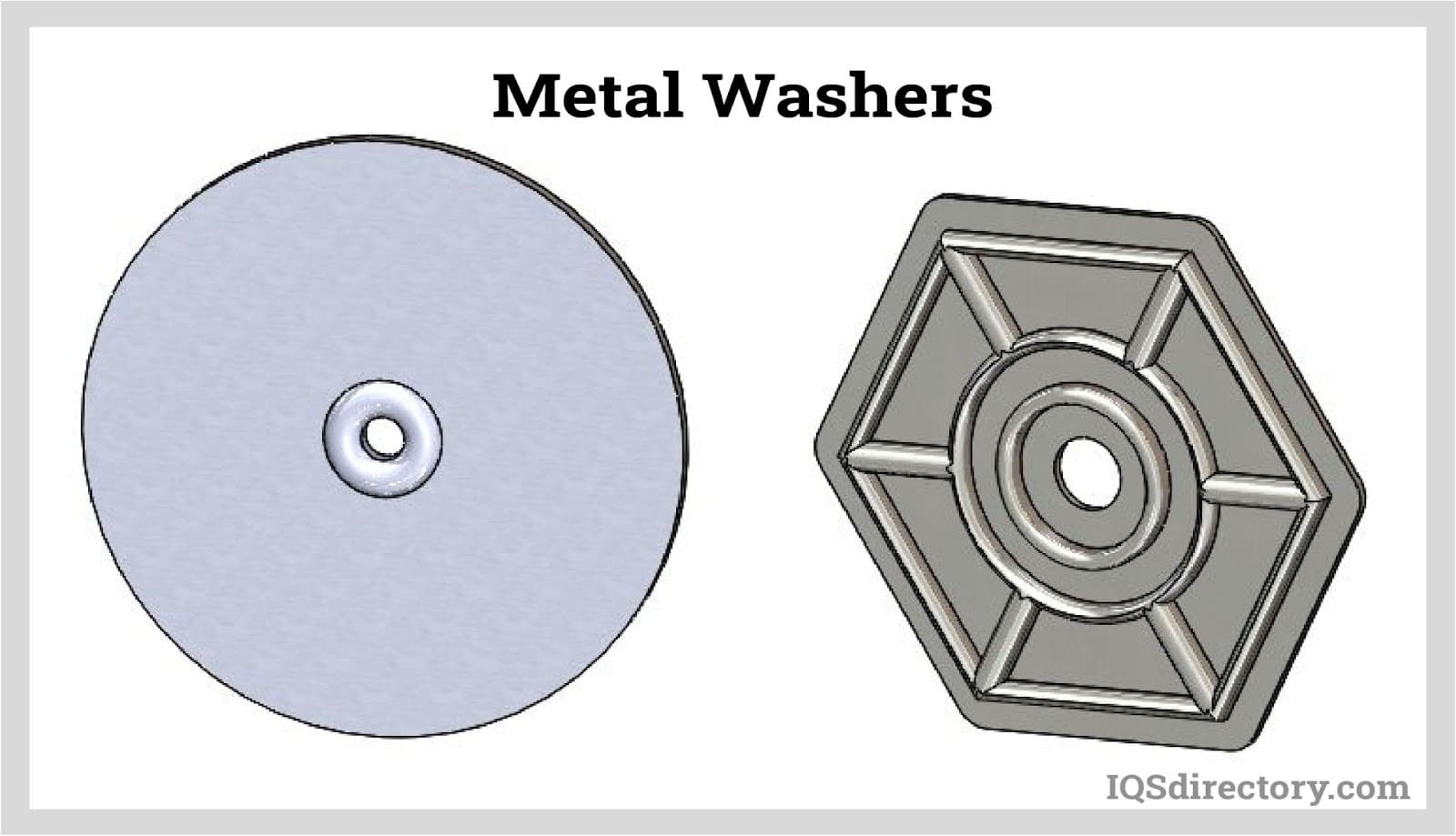

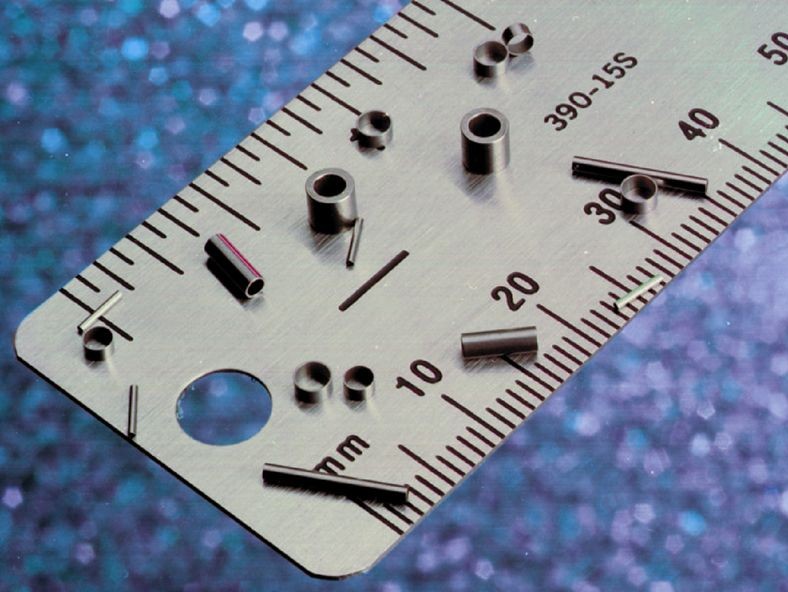

Metal washers are small, flat discs with a hole in the center used to distribute the load of a threaded fastener, such as a bolt or screw. They are commonly used in construction, machinery, and other industries where threaded fasteners are used to secure two or more parts together.. Read More…

We are the metal stampings experts. We have over 30 years of experience creating customized solutions for our customers in a wide variety of industries. We are fully 9001:2008 certified, and we bring that high quality commitment to everything we do.

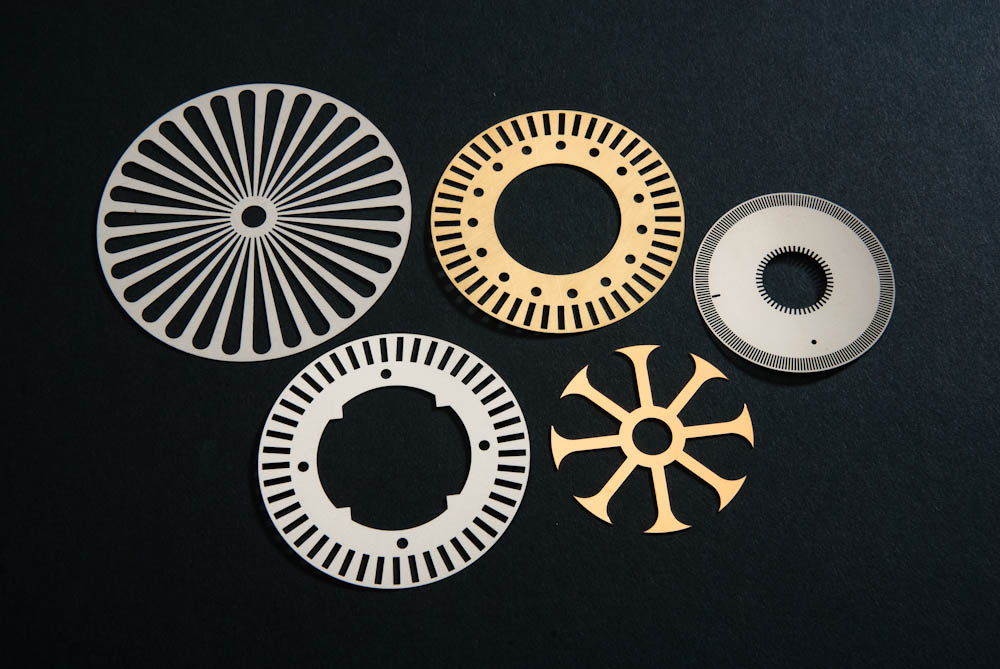

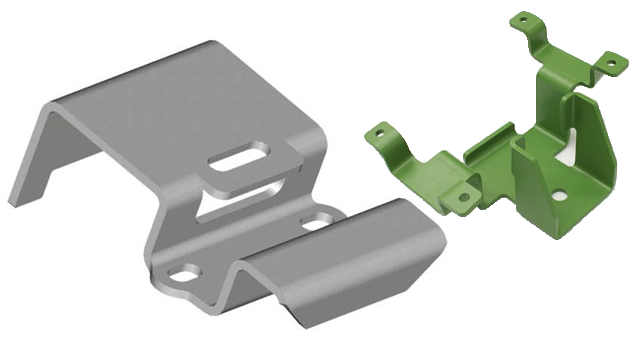

Manufacturer of precision metal stampings for the automotive, electronics, electrical, medical, industrial & consumer markets.

Quality Stamping & Tube Corp has been a leader in the aluminum extrusions and metal stamping industries for over 40 years. We attribute our success to our in-house die-making capabilities and wide range of extruded parts. All of our products are manufactured with quick turnaround and made to be high quality and durable. Our metal stampings can be up to 1/4 inch thick with various metals,...

CSS is a leading international manufacturer of precision springs and metal shaped components. We have been a strategic supplier of progressive stampings, fineblanked stampings, machined stampings, springs and assemblies for 86 years. CSS serves OEMs in a wide variety of industries including medical, aerospace, defense/firearms, automotive, electronics and consumer products.

At Acorn Stamping, we specialize in precision metal stamping that meets the highest standards of accuracy, repeatability, and performance. With decades of experience and a deep understanding of material behavior, we deliver stamped components that serve a wide range of industries, including automotive, electronics, and industrial manufacturing.

More Metal Washer Companies

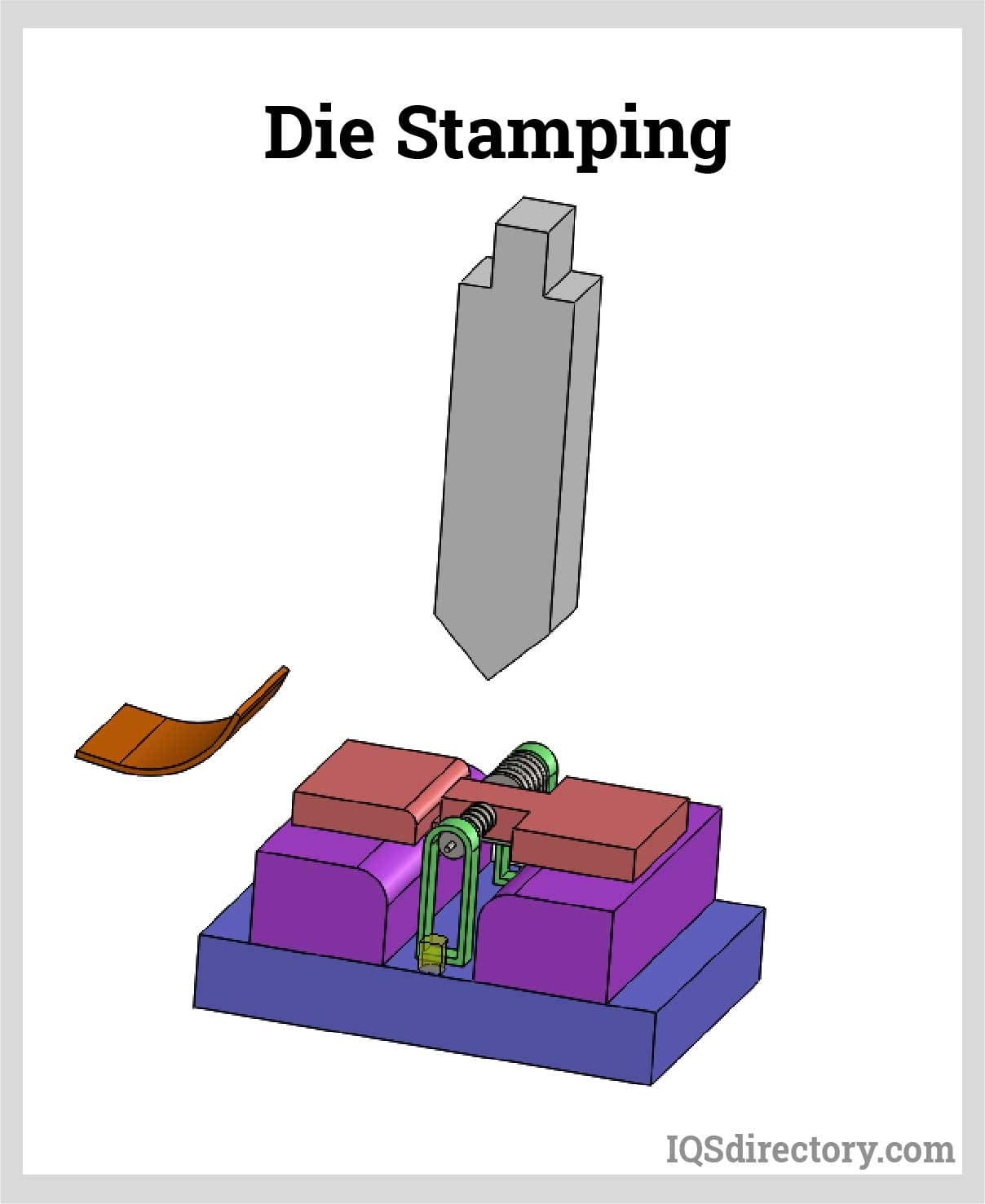

Manufacturing Techniques for Metal Washers

There are several techniques for manufacturing metal washers, including stamping, machining, waterjet cutting, laser cutting, and others. Stamping is the most common manufacturing method, where a flat sheet of metal is fed through a stamping press that cuts and forms the washers to the desired shape. Machining involves using a lathe or mill to remove material from a metal bar or rod to create a washer with the desired dimensions. Waterjet and laser cutting are newer manufacturing techniques that use high-pressure water or laser beams to cut metal sheets into washer shapes.

Types of Metals Used for Metal Washers

The most common metals used for metal washers are steel, stainless steel, brass, copper, and aluminum. Steel is the most popular material for washers due to its high strength and durability. Stainless steel washers are resistant to corrosion and are often used in harsh environments. Brass and copper washers are commonly used in plumbing and electrical applications due to their electrical conductivity. Aluminum washers are lightweight and are used in applications where weight is a concern. The choice of metal for a washer depends on the specific application and the desired properties required.

Considerations Regarding Metal Washers

The creation and use of metal washers comes with some considerations. One of the biggest topics regarding metal washers is the environmental impact of manufacturing them, which requires the use of energy and natural resources. The creation of metal washers can also pose health risks to workers who handle metal sheets and operate stamping presses. Additionally, the use of metal washers can lead to corrosion and degradation of the materials they are attached to over time.

Industry Leaders as Environmental Leaders?

Due to these considerations, many manufacturers of metal washers are implementing policies designed to fight these concerns. Their efforts to combat the negatives associated with metal washers include using sustainable practices and eco-friendly materials, implementing safety protocols and protective gear, developing new coatings and finishes for better protection against corrosion and degradation, and promoting reusability and recyclability through recycling programs. These ongoing efforts aim to make the manufacturing and use of metal washers more sustainable and safe.

Benefits of Metal Washers

Metal washers have many benefits. Metal washers are durable and strong, with high load capacity and resistance to extreme temperatures. They are also electrically conductive and can be used in electrical and electronics applications. Metal washers can be reused and recycled, making them a sustainable choice.

Applications of Metal Washers

Due to their benefits, metal washers have a wide range of applications in various industries, including:

Construction

In construction, metal washers are used to distribute the load of a fastener over a larger area, preventing it from damaging the material it is attached to. They are commonly used in wooden construction, where screws, bolts, and nails are used to secure wooden boards, sheets, or panels. Metal washers are also used in masonry construction, where they serve as spacers between bricks or other materials.

Automotive Industry

Metal washers are used in the automotive industry in a variety of applications, including engine components, suspension systems, and brakes. In engine components, metal washers are used to secure bolts or nuts, providing a reliable connection that can withstand the high vibrations and stresses of engine operation. In suspension systems and brakes, metal washers are used to absorb shocks and distribute forces, improving the overall performance of the system.

Aerospace Industry

In the aerospace industry, metal washers are used in a wide range of applications, including aircraft engines, landing gear, and structural components. They are designed to withstand extreme temperatures, pressures, and forces, making them essential for reliable and safe operation of aircraft.

Plumbing and HVAC Applications

In plumbing and HVAC applications, metal washers are used to create a watertight seal between pipes, fittings, and valves. They are commonly used in faucets, toilets, showerheads, and other plumbing fixtures, as well as in HVAC systems, where they are used to connect ducts and other components.

Agriculture

In agriculture, metal washers are used in various applications, including farm equipment, irrigation systems, and fencing. They are used to secure bolts and nuts, creating a strong and reliable connection that can withstand the harsh environments and stresses of agricultural operations.

Choosing the Proper Metal Washers Supplier

To ensure you have the most positive outcome when purchasing metal washers from a metal washers supplier, it is important to compare several companies using our directory of metal washers suppliers. Each metal washers supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information, or to request a quote. Review each metal washers business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple metal washers companies with the same form.

Broaching

Broaching CNC Machining

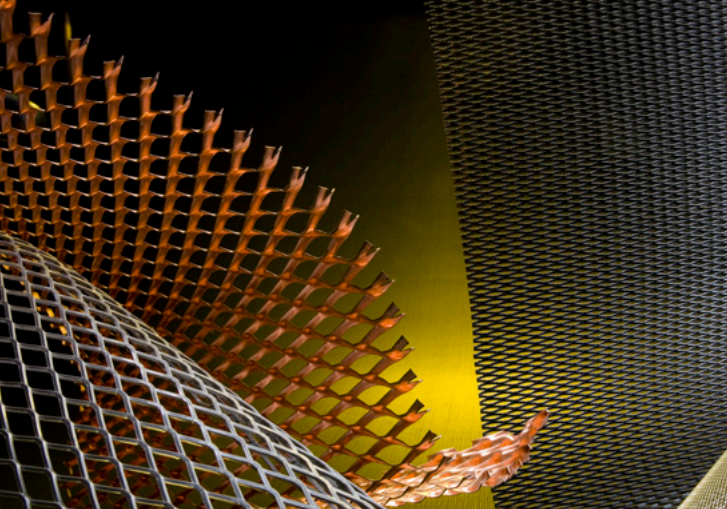

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

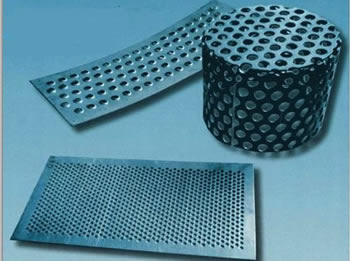

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

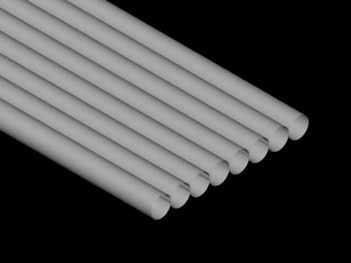

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services