The structure of a metal stamping machine is known as a press. These are powerful pieces of equipment, powered by hydraulics or motors. They come in a variety of sizes, from benchtop versions to large industrial sized versions that take up half a room. The motionless press bed is where the metal being manufactured rests, often held still by a clamp of some sort. A ram, shaped like a long arm, is attached to the power source of the press and moves up and down. The end that makes contact with the metal, be it for brass stamping or another metallic element, has the die attached to make the cuts.

Dies come in a variety of shapes and are often customized to mass produce specific dimensions again and again. They are stabilized on the metallic material by means of the press and then the ram forces the cut by way of a punch. The number of dies utilized at once depends on the machine and its complexity; sometimes only one die is in motion and other times five or more can be punching out pieces from a single piece of sheet metal. Most of the varying elements in metal stamping occur according to the preferences of the company that own the presses, or are due to the demands of the final product.

Broaching

Broaching CNC Machining

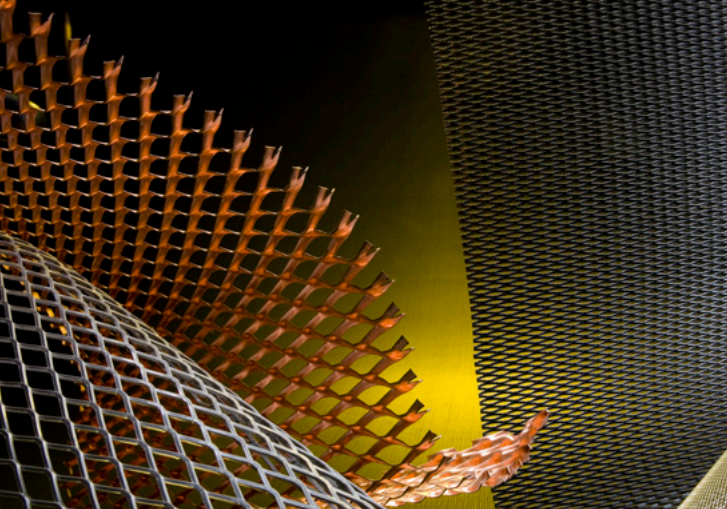

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

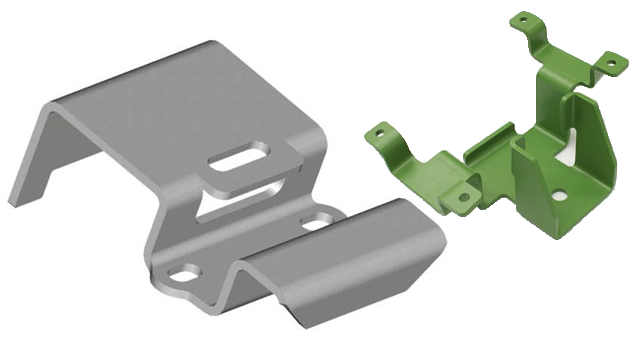

Metal Etching Metal Fabrication

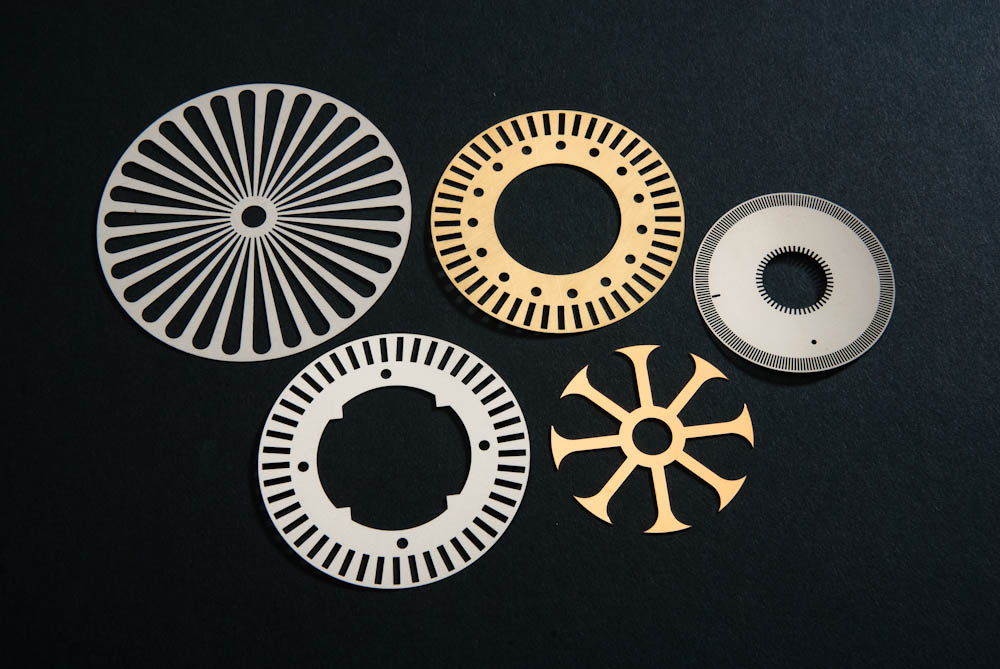

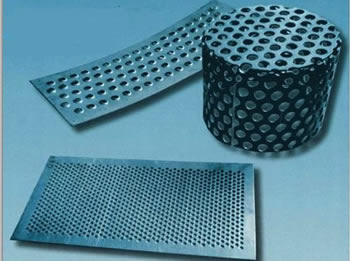

Metal Fabrication Perforated Metals

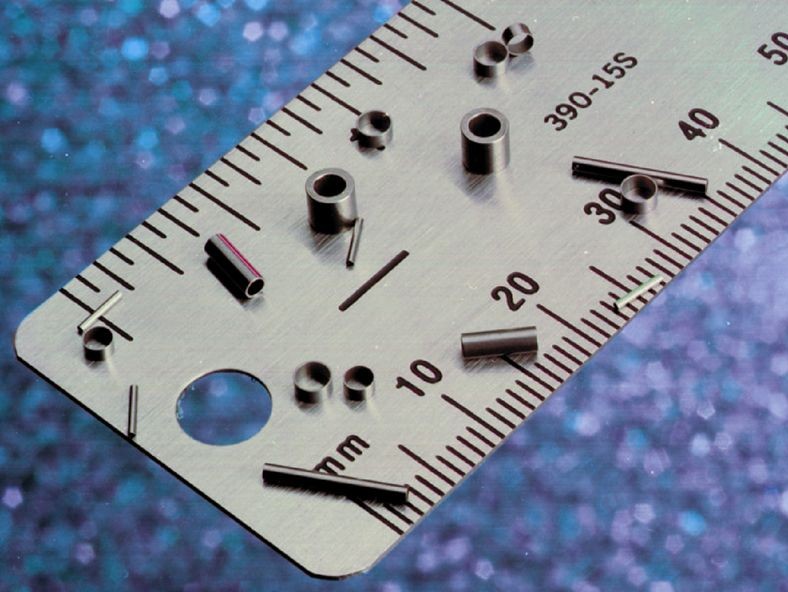

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services