Traverse City Products

Traverse City ProductsRequest A Quote

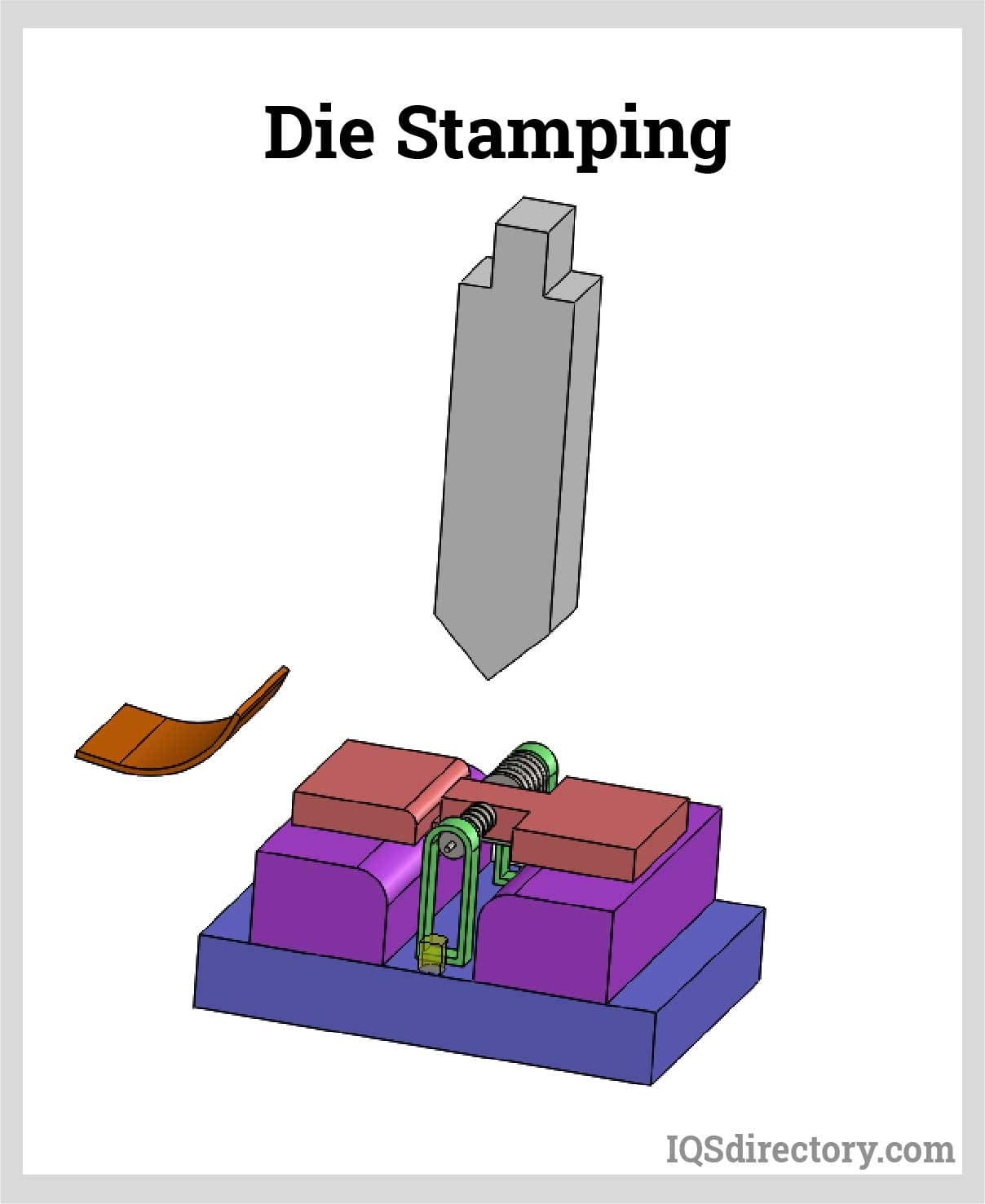

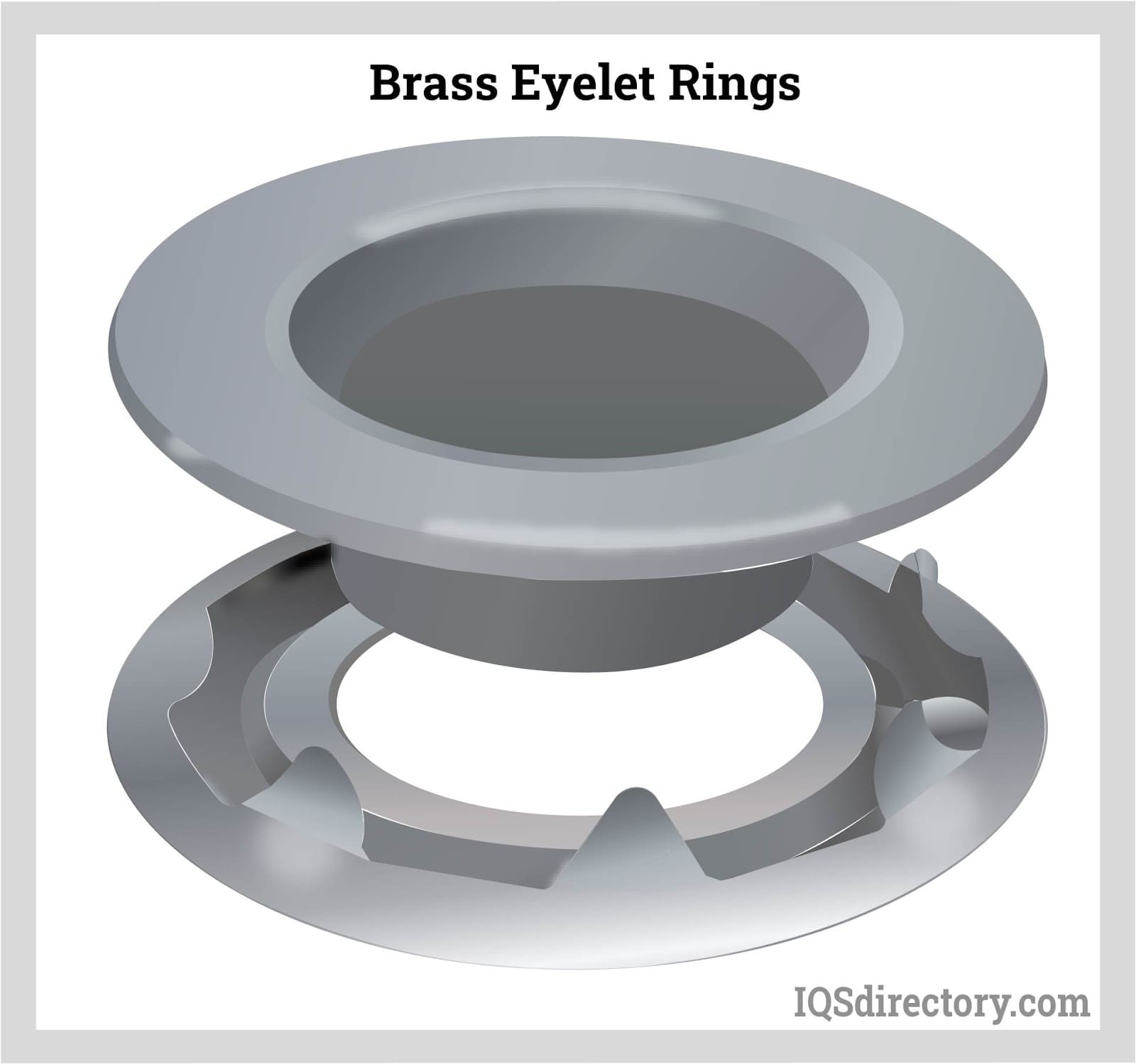

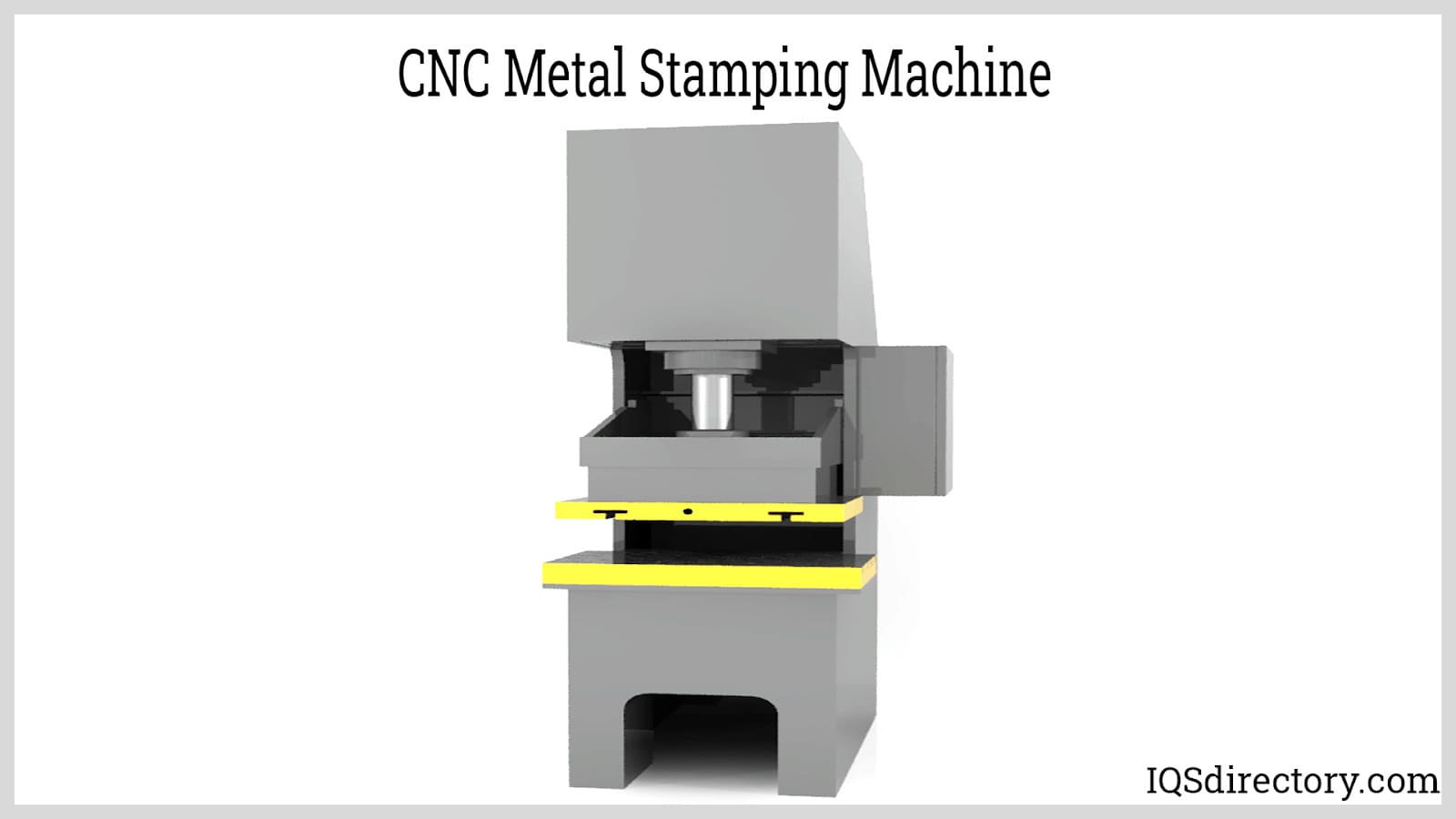

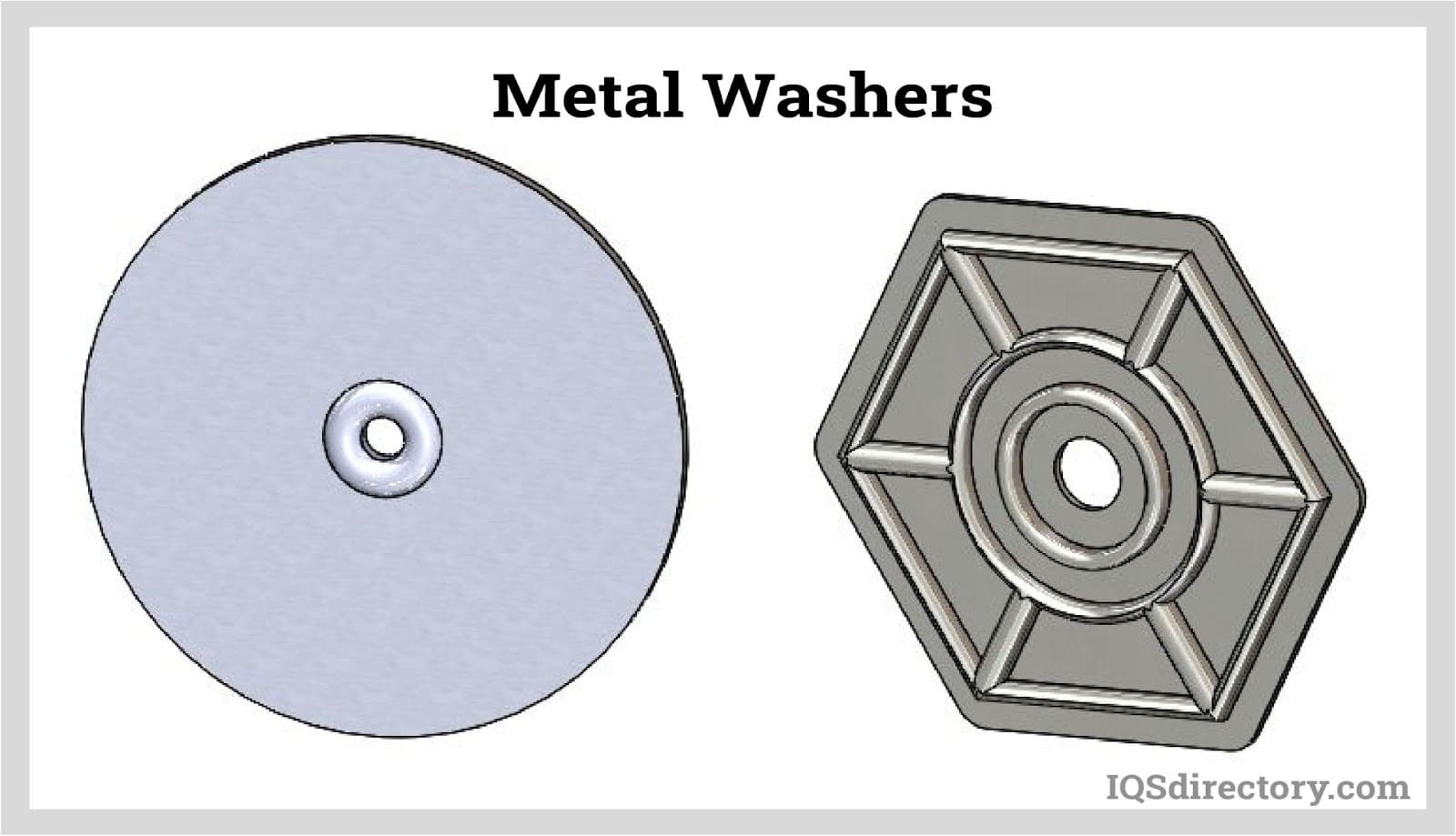

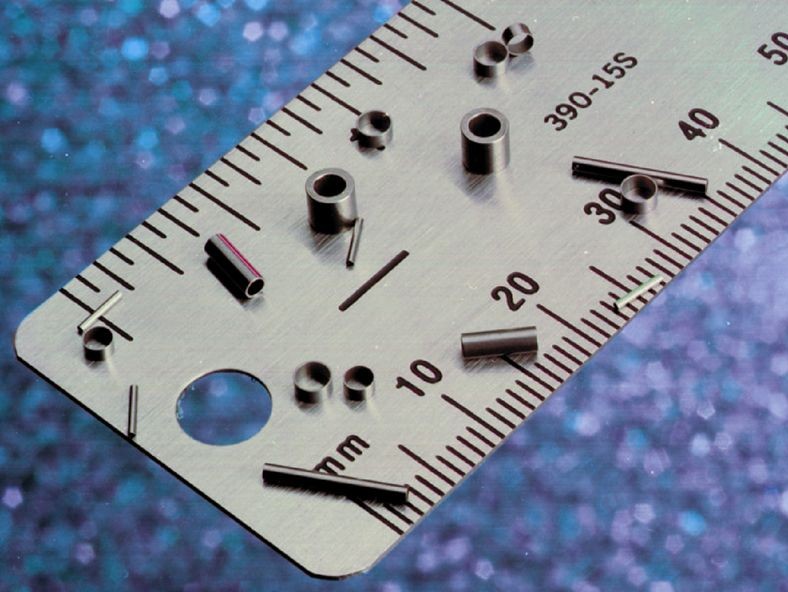

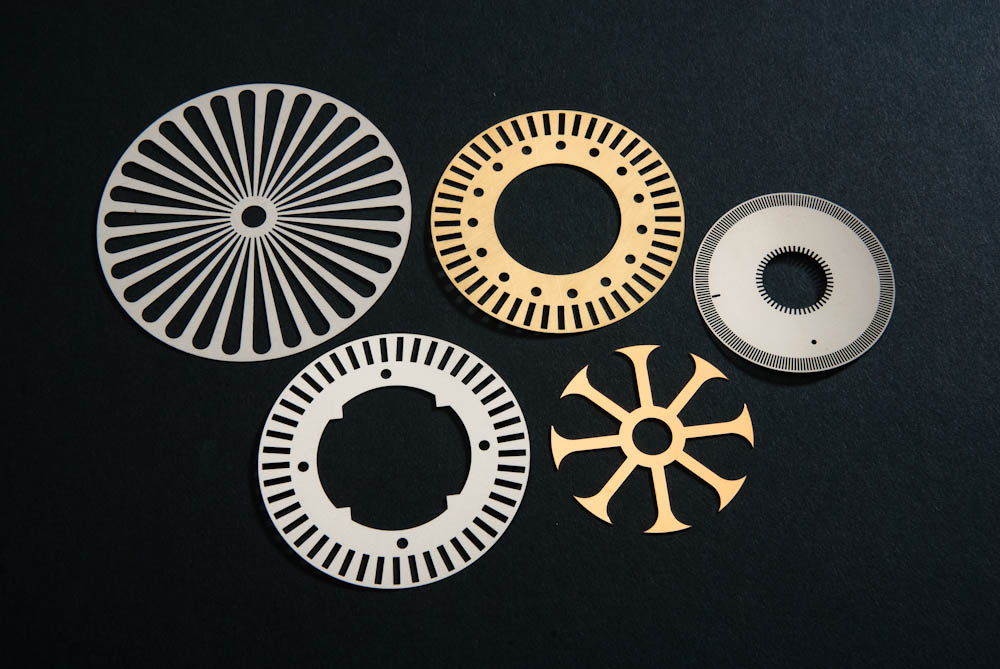

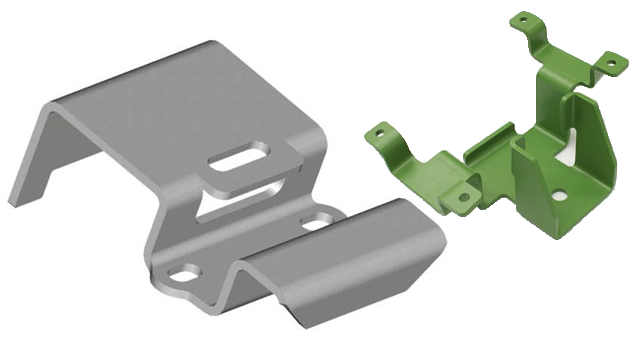

Traverse City, MIAt Traverse City Products, we pride ourselves on our extensive experience and dedication to providing high-quality metal stamping solutions. Over the years, we have refined our expertise to offer a wide range of metal stamping services, each tailored to meet the unique needs of our diverse clientele. Our team works closely with customers to ensure we fully understand their requirements, and we leverage cutting-edge technology and industry best practices to deliver precision-crafted parts. Our metal stamping services are designed to accommodate both large-scale production runs and more specialized, low-volume needs. Whether we're producing complex, intricate components for industries such as automotive, aerospace, or electronics, or simpler, high-volume items, our commitment to excellence remains unwavering. We utilize advanced stamping presses, along with state-of-the-art tooling, to produce parts with tight tolerances, ensuring consistent quality across every piece. We are also focused on providing end-to-end solutions, supporting our clients with design assistance, prototype development, and full-scale manufacturing. Our experienced engineers collaborate with customers to optimize designs for manufacturability, ensuring that cost-effective solutions are achieved without compromising on performance. Additionally, we offer post-stamping services such as assembly, finishing, and packaging, all of which allow our clients to receive ready-to-use products that are fully integrated into their production lines. With a reputation for reliability and precision, we are capable of handling a diverse range of materials including stainless steel, aluminum, and high-strength alloys. Our facilities are equipped with the latest machinery, which allows us to efficiently produce parts with high repeatability and minimal waste. We take pride in our ability to meet tight deadlines and manage projects of varying complexities, delivering exceptional value to each and every one of our customers. Whether the task requires high-volume production or custom, low-run stamping, we bring our expertise, dedication, and attention to detail to every project we take on.

Leading Metal Stamping Companies

More Metal Stamping Companies

Additional Categories: Aluminum

Broaching

Broaching CNC Machining

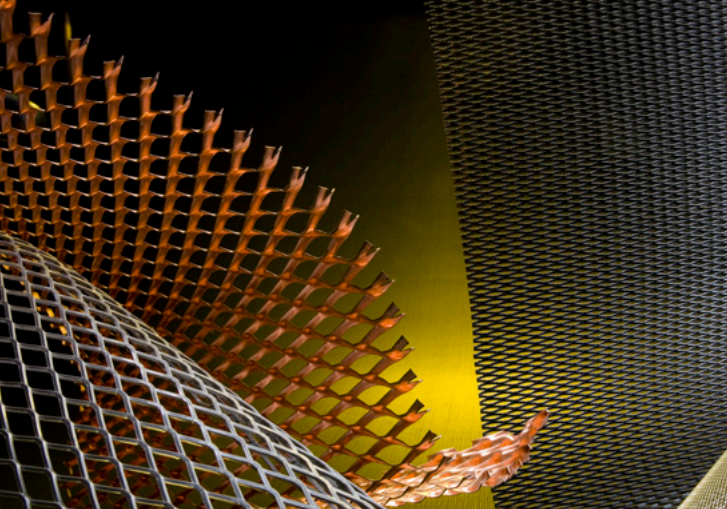

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

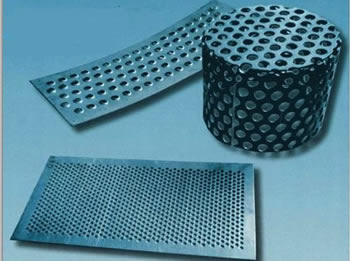

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services